|

The extensive social infrastructure constructed during Japan’s period of high economic growth has, in recent years, begun to deteriorate, leading to major problems for society. A particularly urgent issue is fatigue in the concrete decks of road bridges. In particular, companies operating expressway have been forced to allocate most of their major renovation budgets to work on concrete decks.

Fatigue continues to be an issue with concrete structures. Efforts to resolve

the problem include studying how to apply Miner’s rule to beams and other

members. Wheel loading test machines capable of generating cyclic moving

active loading on a road have been developed and applied to various types

of concrete deck. Recently, a three-dimensional nonlinear finite element

analysis method has been developed by incorporating nonlinear material

models for high cyclic loading. Generally, though, research in this field

has taken a structural engineering approach. On the other hand, a current

problem with concrete decks is extensive damaged caused by the use of salt

(NaCl) as a de-icing agent. Fatigue caused by traffic further accelerates

the damage, resulting in visible damage and diminished structural performance.

Resolving these problems requires a concrete-engineering approach.

This report summarizes topics related to fatigue studies of concrete structures

that have been discussed in the past two years by this subcommittee established

by the JSCE Concrete Committee. The report describes the activities of

two working groups (WGs): the WG for elucidation of mechanisms (WG1) and

the WG for performance evaluation (WG2).

WG1 has examined fatigue failure mechanisms relating to concrete and steel reinforcement and the bonding between them, as well as fatigue mechanisms relating to reinforced concrete members. The WG also proposed a technique for assessing fatigue damage in reinforced concrete structures and described examples of concrete foundations for wind turbines, etc.

On the other hand, WG2 examined concrete road bridge decks and discussed

ways that their quality and performance may be maintained at each stage

of their life cycle: design, construction, and maintenance. The WG argued

that performance evaluations, particularly those of the entire superstructure

(main girder, concrete deck, waterproofing system, and pavement), can lead

to improved durability and fatigue resistance of concrete decks in harsh

environments, such as those in which de-icing agents are used. The report

of this part was based on a result of discussions among experts in concrete

decks and pavements.

The above clarifies the outstanding research and technological achievements being made in this field. Significantly, this work by the Concrete Committee has been carried out with the involvement of many junior and mid-level researchers and engineers. The committee is expected to continue studying fatigue in concrete structures and developing technologies for resolving the issue in the years to come.

The working group for elucidation of mechanisms (WG1) was established to

determine the extent of current knowledge about concrete fatigue. The results

of many fundamental studies on fatigue failure in reinforced concrete structures

were collected and analyzed. A second purpose was to discuss appropriate

methodologies for evaluating fatigue damage in consideration of the latest

developments in numerical analysis technology. Three workshops were held

in the group’s first year. In the second year, several research topics

were selected for particular focus and studies were carried out. The results

of these studies have been compiled in Volume II.

Firstly, current methods of evaluating fatigue damage in reinforced concrete

structures were examined and several research questions were raised from

this process. What is the phenomenon of fatigue in reinforced concrete

structures? What actions cause fatigue in structures? How does the response

of individual members affect overall structural performance? After these

questions were raised, issues related to appropriate methods of evaluating

fatigue in structures were discussed.

This discussion identified the following issues concerning fatigue mechanisms.

a) General issues relating to the modeling of cyclic actions

Specifically, there is a need for more studies

to develop reasonable modeling methods that can take into

account

the time-history of cyclic actions and appropriate methods of modeling

the cyclic actions caused by

force transferred

from vehicles, etc.

b) General issues relating to the evaluation of member responses that

are generated in structures by cyclic actions

Specifically, there is a need to discuss the following:

methods of estimating three-dimensional response

stress

histories associated with rotation of the principal stress direction; further

development of non-linear

constitutive models;

and indexes and techniques to quantitatively evaluate the amount of damage

to

materials or their degree of failure.

c) Issues relating to the verification of RC decks of road bridges

subjected to moving loads

In particular, it is necessary to consider the

intensity and frequency of loads and uncertainty regarding the

loading

position (wheel tracking position).

On the subject of the maintenance of RC structures, the following issues

were identified.

a) A method should be established for evaluating load-bearing capacity

after some damage has occurred.

b) A technology needs to be developed to determine whether fatigue has been caused by the combined

effect of cyclic loads and environmental

action, or by the effect of one alone.

Secondly, to clarify the mechanism of fatigue in reinforced concrete, academic

research results concerning fatigue in concrete, steel reinforcement, and

the bond between concrete and steel reinforcement were collated and analyzed.

An attempt was made to summarize issues concerning the effects of load

amplitude and material deterioration (freezing-thawing action, alkali-silica

reaction (ASR), and the presence of water). These must be taken into account,

but so far they are not well understood. Further, the impact of corrosion

of the steel reinforcement on fatigue in reinforced concrete was investigated.

The investigation and analyses suggests that further experimental data relating to reinforcing bar fatigue under both tension and compression (reversal cyclic loading) are still needed. Also, requirements for further experimental studies relating to fatigue in the bond between concrete and reinforcing bars, especially considering loading rate, reinforcing bar corrosion, and the effect of liquid water, were pointed out.

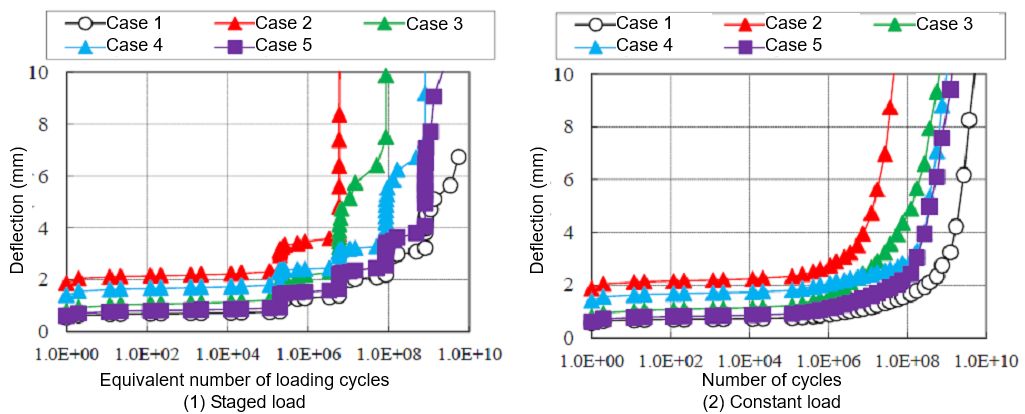

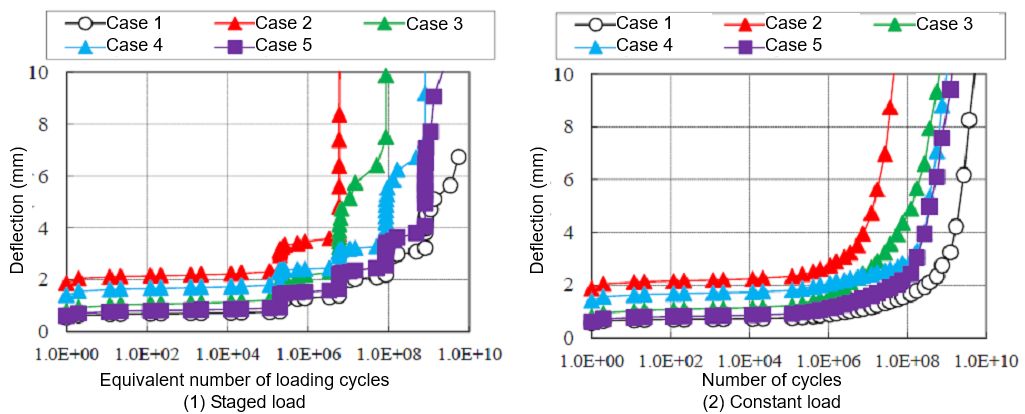

In addition, we also organized the results of the latest experiments and

numerical analyses. First, reinforced concrete slabs subjected to fatigue

damage were selected as examples of dynamic non-linear response analysis.

Figure A shows evaluations of various influencing factors (strength of

concrete, loading speed, boundary conditions, etc.) using sensitivity analysis.

This study revealed much information about fatigue in reinforced concrete

structures that would have been difficult to obtain only through experiments.

Fig. A. Examples of deflection analysis of RC slabs under moving loads obtained by 3D non-linear FEM

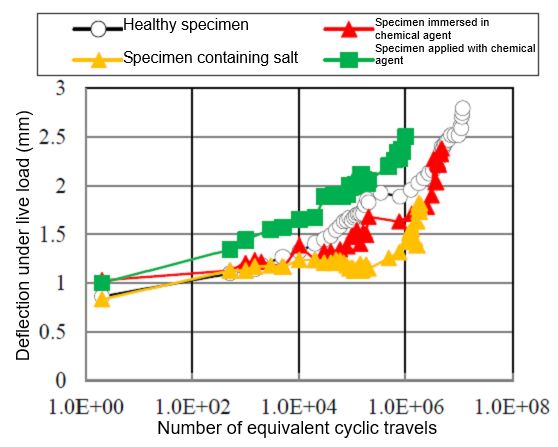

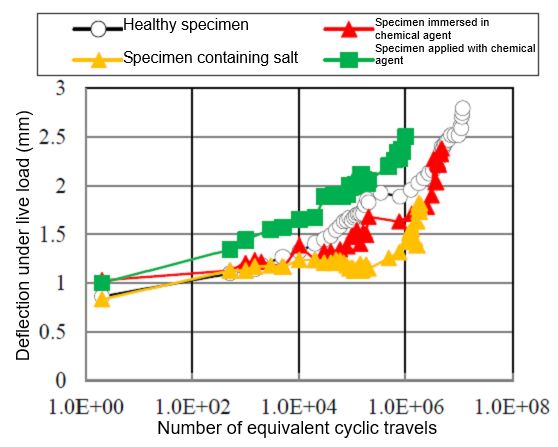

Moreover, the Actual structures are affected by deterioration caused by

environmental conditions and material properties, as well as by the effects

of fatigue. Figure B shows the results of studies that evaluated the progress

of deterioration due to chloride attack or ASR; those coincide with fatigue

damage in RC slabs. The study focusing on chloride attack suggests that

the performance of an RC slab is influenced by the history of environmental

action leading up to corrosion, as well as by the chloride ion content

in the concrete and the amount of rebar corrosion. Another study evaluating

the failure of reinforced concrete due to fatigue caused by environmental

and meteorological actions and the effect of water in cold climates is

also introduced. A special experimental study that examined the effects

of water and wheel speed is listed together in the report. Further, information

about evaluating damage caused by fatigue in RC members that had been repaired

and strengthened was revealed.

Fig. B Wheel load travel test results under different conditions of corrosion

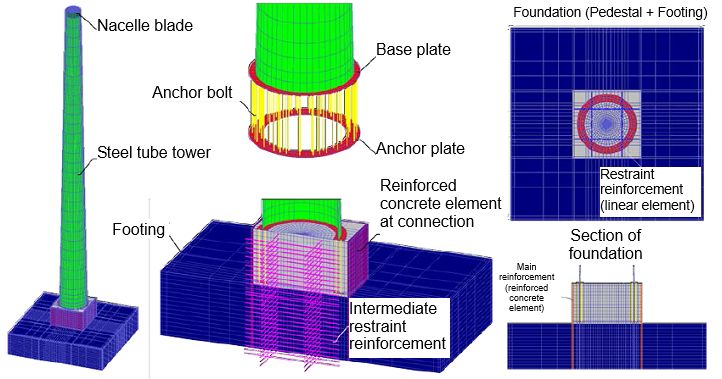

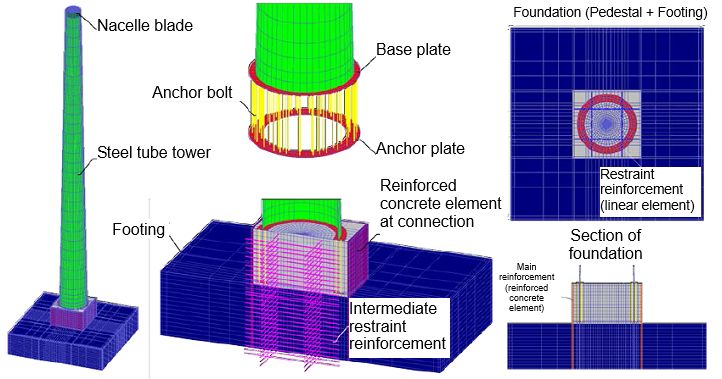

The phenomenon of fatigue must be considered in other types of structures, not only in road and railway bridges. A pioneering study which elucidated the damage process and failure mode due to fatigue in the RC foundation of a wind turbine (Fig. C) is presented in our report. An S-N curve shows the limit state of the foundation supporting the wind turbine tower when a repetitive load of constant amplitude is applied in a single direction. As an index, the secondary invariant of average deviatoric strain of the concrete at the foundation connection was used.

Fig. C Example of damage process and failure mode due to fatigue at the connection in the reinforced concrete foundation of a wind turbine

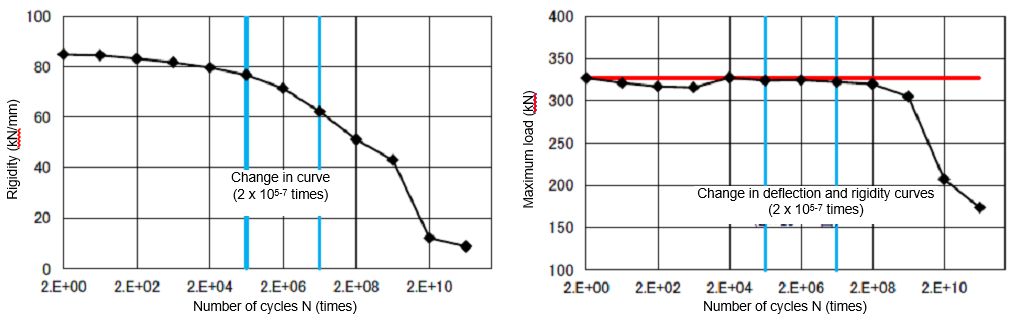

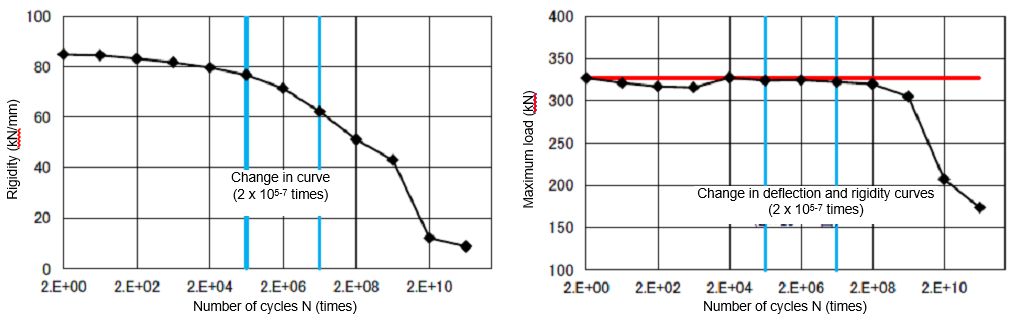

Lastly, a technique which enables us to evaluate structural damages in

a consistent way at any timing, rather than combining evaluations of failure

at ultimate load and fatigue failure, was proposed by the working group.

Although it is difficult to measure the changes in residual bearing capacity

experimentally, a recent development in numerical analysis technology makes

it possible through simulations. To verify the proposed method, a non-linear

finite element analysis was performed for RC beams and slabs. However,

this proposal for determining residual bearing capacity did not give the

expected results for an RC beam that suffers flexural failure; this is

possibly because the effect of concrete fatigue damage on bearing capacity

is relatively small. In contrast, the reliability of the proposed method

was proved in the case of an RC slab that suffers shear failure (Fig. D).

Fig. D Simulation of residual bearing capacity of reinforced concrete slab

under the action of wheel load

We thus have decided to continue the examination of the applicability of

this method to other requirements of structural performance, such as serviceability.

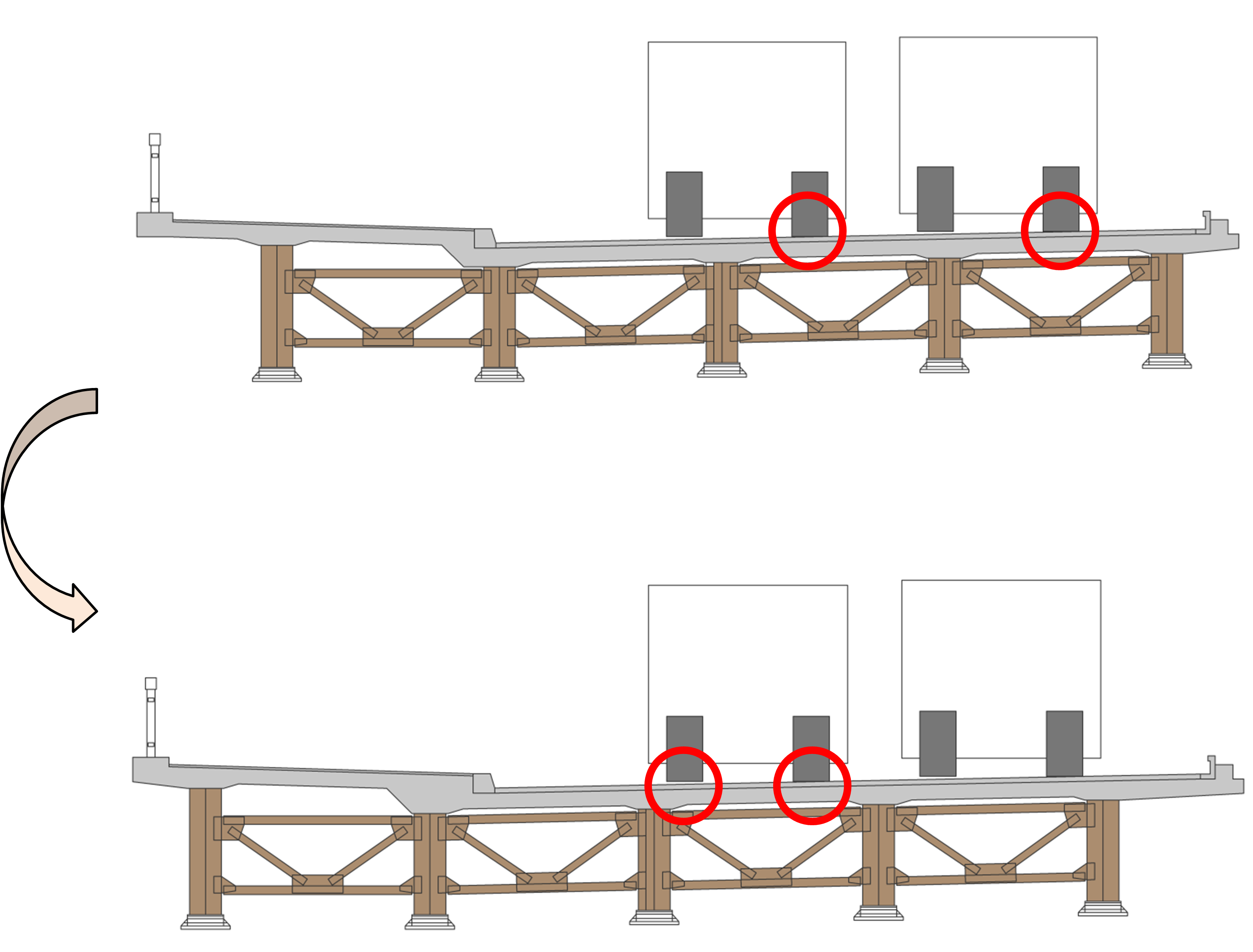

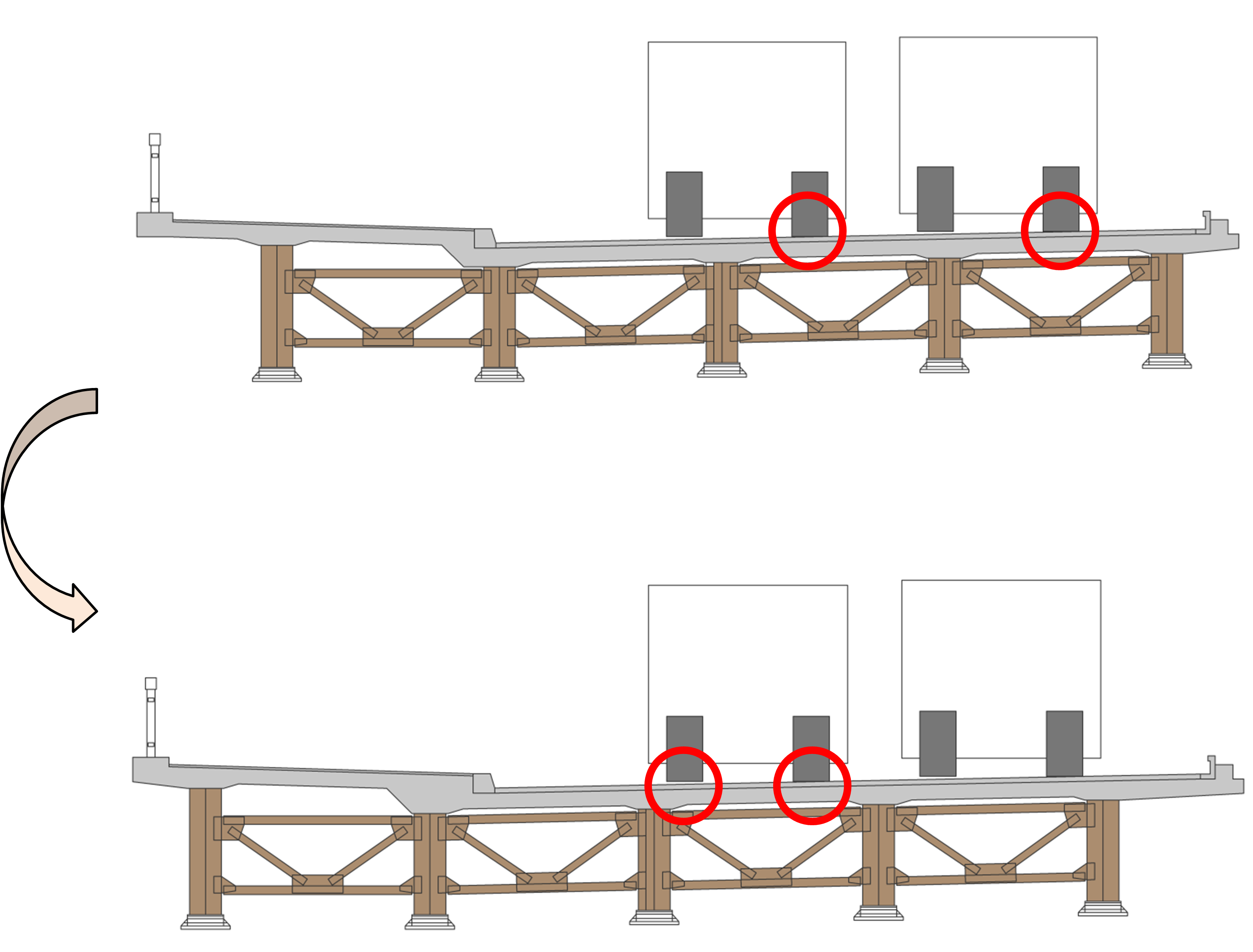

The WG2 studied the design, construction, and maintenance of the reinforced concrete decks of road bridges with the aim of maximizing their overall performance. Information about recent cases of damage to reinforced concrete decks was collected and measures to prevent such damage were studied. Damage caused by fatigue in road bridge decks has been a problem since the 1960s. Grid-like cracking is noticeable on the decks of road bridges designed to the old standard (Photo A). Revisions of the standard have dealt with the problem of fatigue damage by increasing the minimum slab thickness and the amount of steel reinforcement. However, in addition to increasing the deck strength, the WG suggests improving the design of the girders in order to prevent damage and deterioration. For instance, by taking the number of main girders and their spacing into account along with the vehicle loading positions during the design stage, it is possible to considerably reduce damage to the slabs (Fig. E).

Photo A Grid-like cracking on underside of deck

Fig. E Reduction in response value by revised main girder layout (upper: conventional layout; lower: proposed layout)

Fatigue failure due to heavy traffic loading is not the sole cause of damage

to decks. Concrete on the upper surface of a reinforced concrete deck can

fracture and become pulverized (Photo B).

Photo B Pulverized concrete on reinforced concrete deck

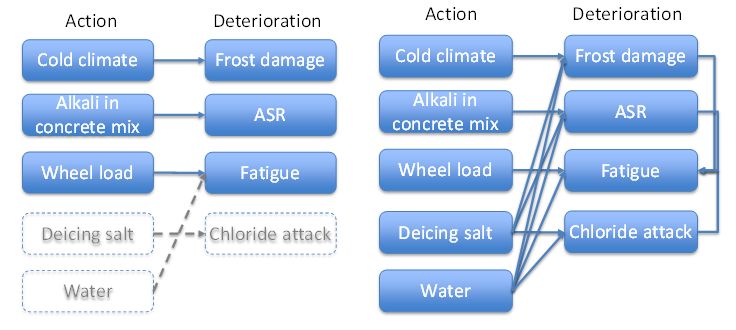

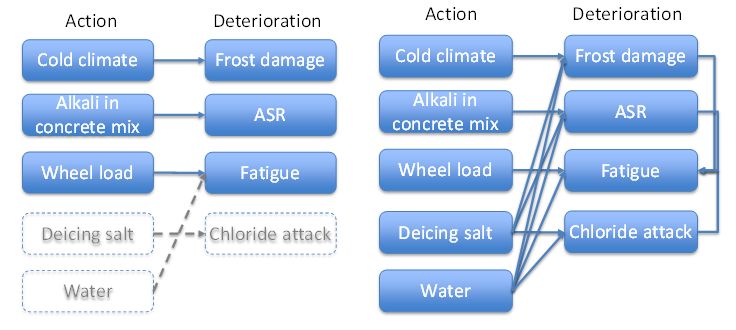

The mechanism by which concrete becomes pulverized has not been clarified,

but the phenomenon is mostly seen in environments in which anti-freeze

agents are used. Previously, a clear one-to-one relationship was thought

to exist between various actions on a deck and deterioration (left side

of Fig. F). However, anti-freeze agents not only establish a new form of

deterioration – salt damage – but the action becomes more complicated to

elucidate. Therefore, traditional materials design methods may not be able

to prevent deterioration.

Fig. F Relationship between assumed actions and deterioration in deck design (left: conventional understanding; right: environment with anti-freeze agent)

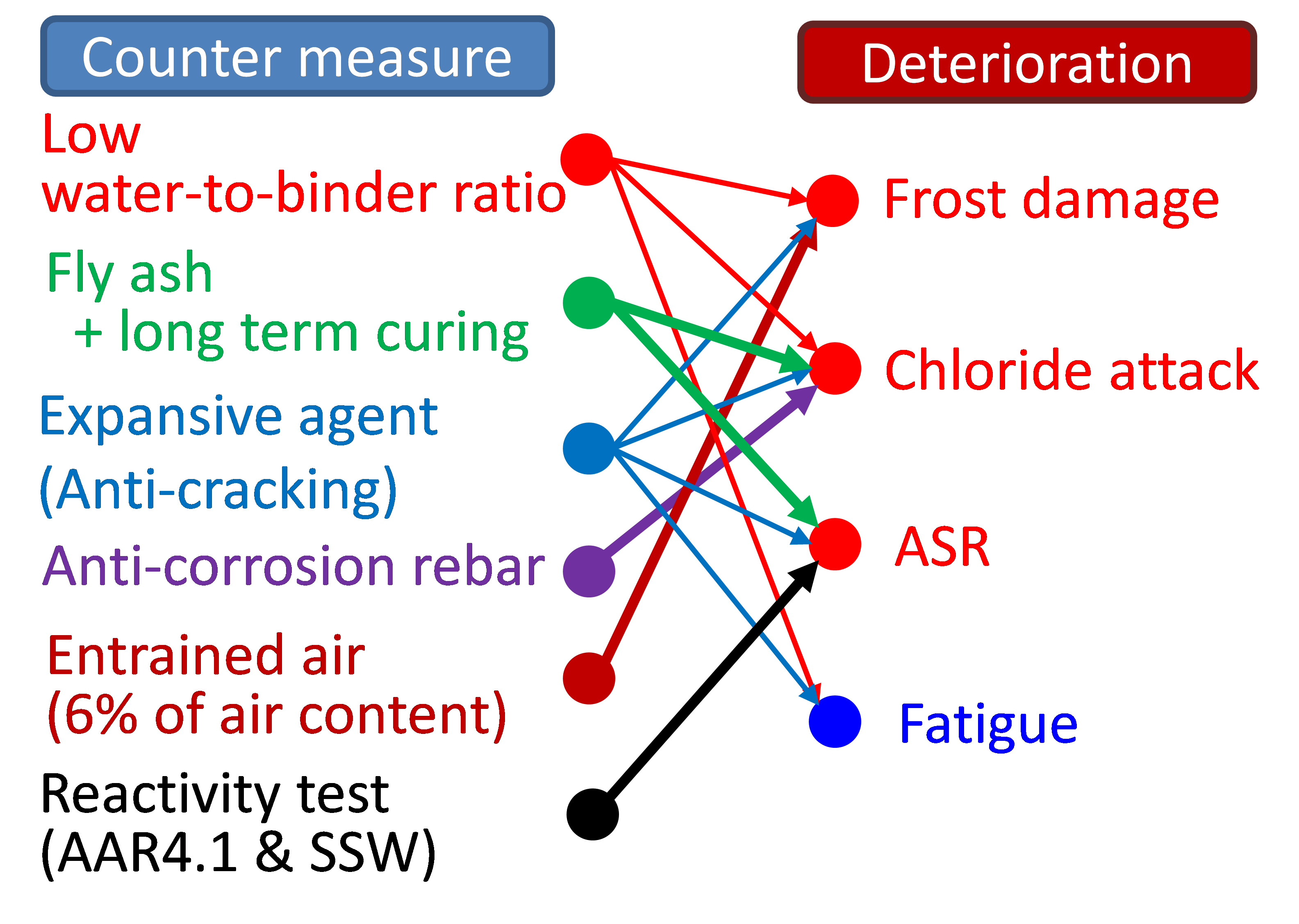

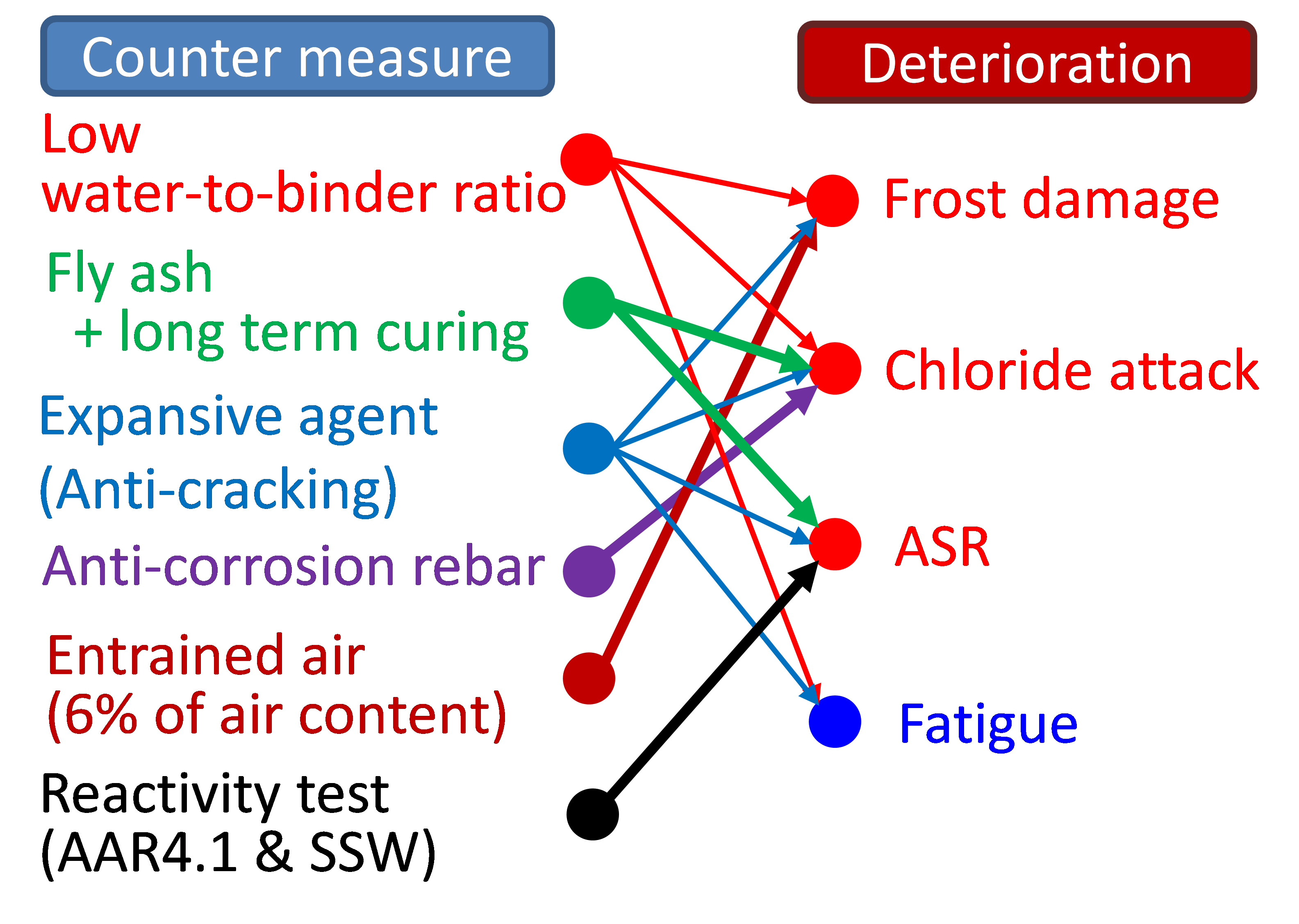

To elucidate the mechanism as a step toward preventing pulverization, a test deck was constructed on a reconstruction road in the Tohoku region of Japan. Measures were implemented against all possible forms of deterioration by considering the combined action of salt in the anti-freeze agent and alkali ions. Furthermore, redundant measures were applied, resulting in a system that prevents deterioration (Fig. G). Fly ash was used in the concrete to inhibit salt damage and the alkali-silica reaction (ASR).

Fig. G Example of highly durable deck design by redundant protection and

use of admixture

Photo C shows a case of potholes in the asphalt pavement covering a deck

slab. Potholes develop when the waterproofing layer between the slab and

the asphalt pavement becomes detached. Because some types of finishing

agent used during deck construction can reduce the bonding force with the

waterproofing system, all materials should be evaluated for compatibility.

Moreover, if water collects within the asphalt layer, potholes can easily

develop. The water easily enters the slab through gaps in the layer and

may collect under the layer (Photo D). Water collecting on the upper surface

of the reinforced concrete deck significantly reduces fatigue resistance.

Hence, decks should be constructed so that they cannot collect water.

Photo C. Potholes

Photo D. Water collects under waterproofing layer

Proper drainage is critical for preventing water from collecting and requires proper planning and upper-surface finishing of a deck to a flat and smooth finish. However, when the surface is manually finished, as is currently done, the surface may be uneven, allowing water to collect after rain (Photo E). To prevent this, the WG has developed technologies to improve the flatness of the surface. Photo F shows a simple finishing machine developed by the WG. Used in the finishing processes, the machine reduces the finishing error to about ±2 mm.

Photo E Water collects on deck after rain

Photo F Simple finishing machine prototype ensures flatness

A concrete deck does not function in isolation. When constructed together

with a pavement and waterproofing layer, it allows for the smooth travel

of wheel loads. Hence, concrete slabs should be treated as complete systems.

To avoid problems at the interfaces between components of a deck system,

a means for transmitting information between construction workers in different

trades is required.

|