The Asahan Hydroelectric Power Generation Project

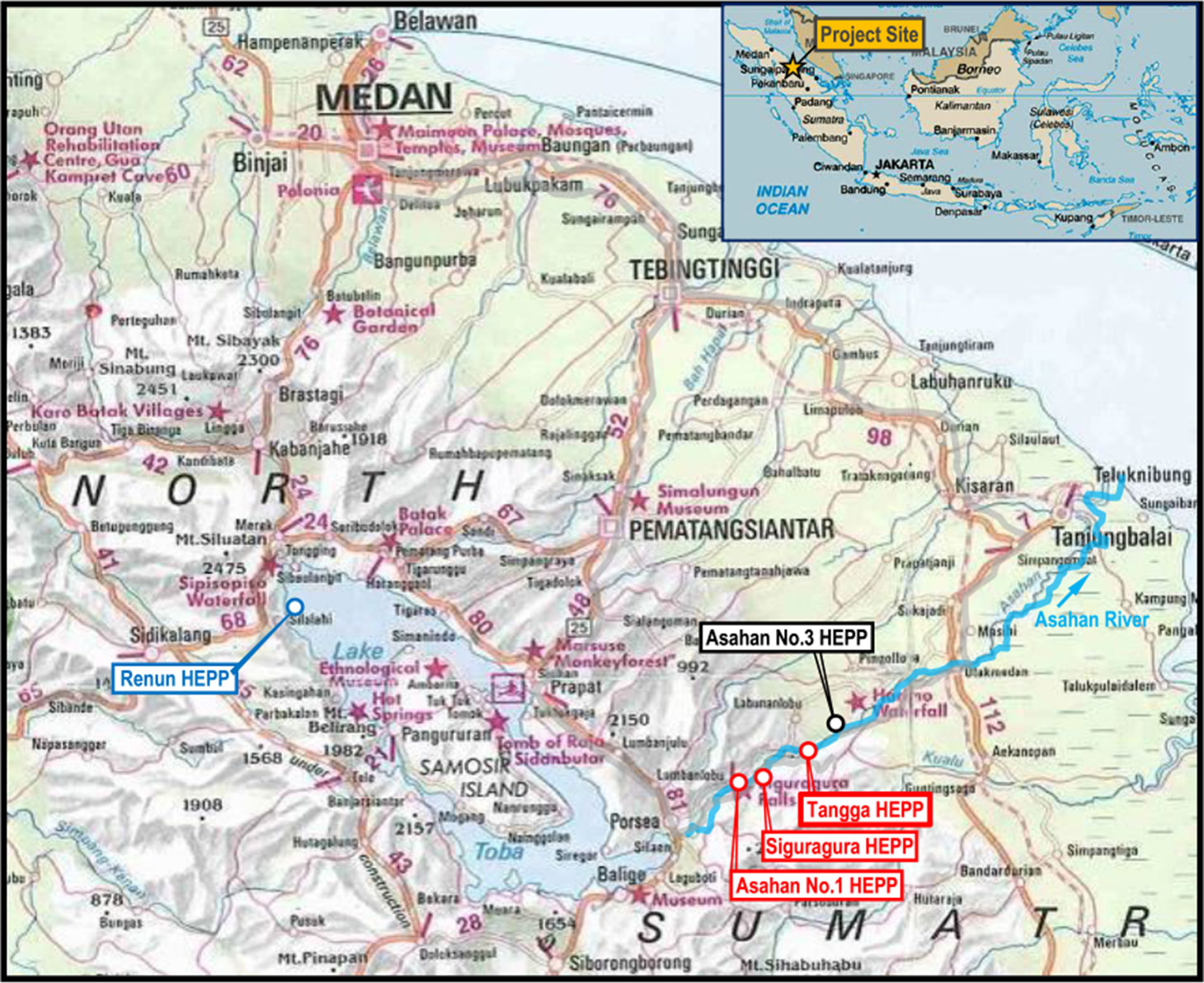

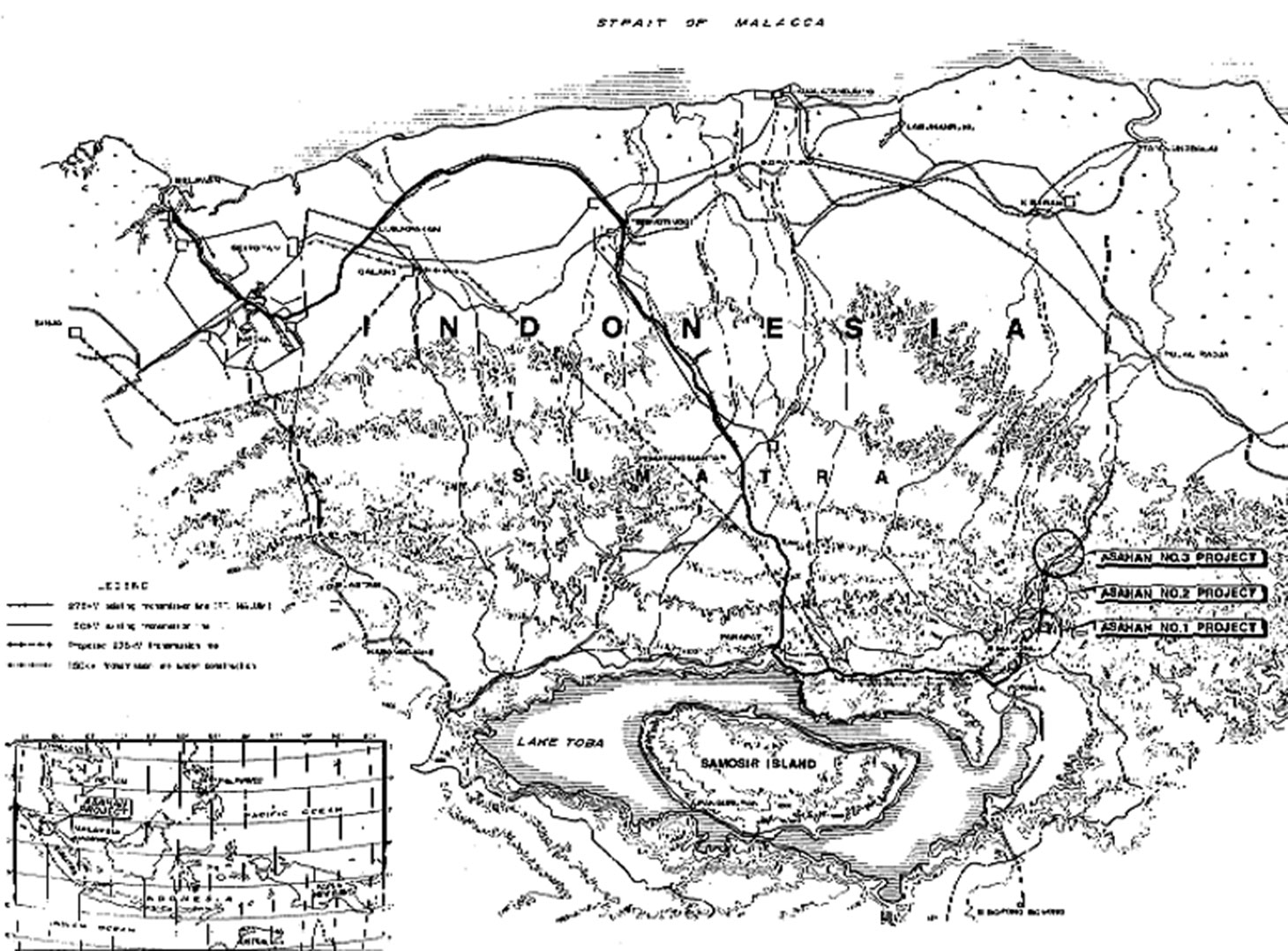

The Asahan River is the only river that flows out from Lake Toba in the center of North Sumatora, Indonesia. The history of the Asahan River development project goes way back to the Dutch colonial period. The Dutch colonial authority found the great potentiality of the river for a hydroelectric power development in Indonesia and carried out a survey of the area to construct a hydroelectric power plant in the early 1900s, which didn’t materialize due to World War II. After many twists and turns, the Japanese government decided to fund for the comprehensive development plan of the project in 1969.

Development at the site of the Asahan River was sought for many years, and the Asahan hydroelectric power generation plan was brought to fruition by planning to supply electricity to an aluminium smelting plant, which uses a large amount of electricity.

The Japan Society of Civil Engineers decided to feature this project in its archives for the following reasons.

-

1)Taking advantage of the area’s enormous potential for hydropower

Lake Toba Indonesia is the largest caldera lake in the world. An average of 100 m3/s of water from the lake flows down the Asahan River for 150 km before reaching the Strait of Malacca. The Asahan River discharge and water head of the terrain have great potential for generating hydroelectric power. -

2)Joint development between Indonesia and Japan

PT. INALUM (Indonesia Asahan Aluminium), a joint venture between the Indonesian government and Japan Asahan Aluminium, was founded in 1976 to take responsibility for the construction and running of the Asahan Hyrdroelectric and Aluminum Project. The construction was carried out with the latest Japanese design and construction technologies at the time. -

3)Contribution to increase industrial development and employment in Indonesia

The aluminum smelting industry and the export business of aluminum ingots make a significant contribution to Indonesia’s economic and industrial development.

1Project Background

1.1Joint Development between Japan and Indonesia

The development of the Asahan River to utilize its huge potential for hydropower has been earmarked since the Dutch colonial period. After many twists and turns, a comprehensive development plan for the Asahan River was formulated in the 1970s thanks to government funding. After the oil crisis in 1973, the Japanese aluminium smelting industry sought overseas production bases, and so as part of the plan, a proposal was formulated to develop a package proposal consisting of hydroelectric power generation and an aluminium smelting business, which would require a large amount of electric power. Then, after receiving the green light from the Indonesian government to proceed with the development of both hydroelectric power generation and aluminium smelting infrastructure, the Asahan Hydroelectric and Aluminium Project was off to the races. As a construction and operation company, Japan Asahan Aluminium was established as a consortium of 12 Japanese companies, and PT. INALUM (Indonesia Asahan Aluminium), a joint venture between the Indonesian government and Japan Asahan Aluminium, was founded in 1976 to take responsibility for the construction and running of the project.

1.2WContribution to Increase Industrial Development and Employment in Indonesia

The aluminium smelting industry and the export business of aluminium ingots made a significant contribution to Indonesia’s economic and industrial development. The construction of the hydroelectric power plants was carried out with the latest Japanese design and construction technologies at that time, and the construction work was implemented by a construction company formed as a joint venture between Japan and Indonesia. In addition, roads, houses, etc. linked to the construction of the hydroelectric power plants were also constructed. The employment of Indonesian construction workers during construction and the subsequent operation by PT. INALUM also created many job opportunities for Indonesian people, which had a significant impact on the country’s economic development and the number of jobs available.

2Project Chronology

2.1Surveying & Planning

The history of the Asahan River development project goes way back, with hydropower development and aluminium smelting efforts beginning during the Dutch colonial period. Work to measure the flow rate of the Asahan River started in 1915, and construction of a hydroelectric power plant began in 1941. The construction of this hydroelectric power plant, however, would later be suspended due to the invasion of Sumatra by the Japanese army in World War II. After that, Japan also made plans to build a hydroelectric power plant during the war, but the development was suspended yet again at the end of the war in 1945.

Following World War II, Western countries proceeded with surveys and considering the possibility of such a construction, but it was difficult to secure funds and ultimately the construction of a hydroelectric power plant never materialized. At the request of the Indonesian government, the Soviet government carried out a feasibility study in 1962, but no such construction came to fruition due to the change in political regime in Indonesia in 1965.

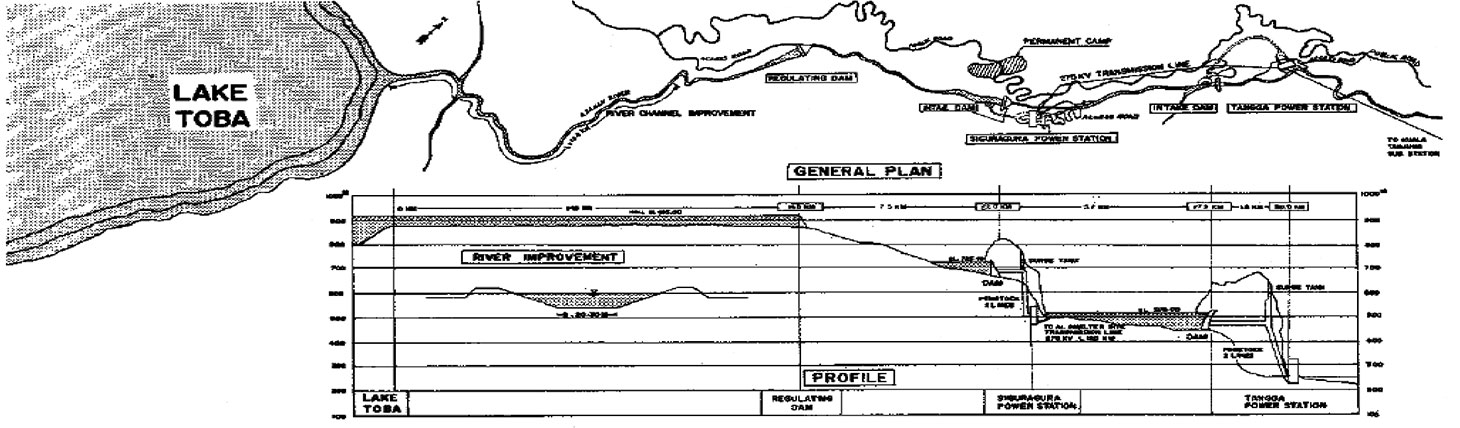

Based on the policy of the Indonesian government in 1968, a comprehensive development plan was formulated between 1969 and 1972 with funding from the Japanese government. It was in this plan that a proposal to build five power plants on the Asahan River was considered, and the Asahan Power Plant No. 2 was set to be used for aluminium production. Furthermore, from the viewpoint of ensuring safety, Power Plant No. 2 was set to be divided into Siguragura Power Station and Tangga Power Station. Nippon Koei, which formulated a comprehensive development plan and carried out detailed investigative and design work under JICA, set up a special office for the Asahan project in order to manage its design and construction. Up to 27 engineers were dispatched to the construction site, and the knowledge and experience of design and construction management gained in the Asahan project proved to play a big part in Nippon Koei’s subsequent business development.

The comprehensive development plan also contained an initiative to construct a power plant that would change the watershed from the Renun River and Batang Toru River, which were outside the Lake Toba watershed. Among them, the Renun Power Plant was completed in 2006 with Japanese ODA funds and design and construction overseen by Nippon Koei.

2.2Establishing of Project Task Force and Raising of Funds

In 1975, with the consent of the Indonesian government and the Japanese government, the Government of Japan began providing financial assistance. In July 1975, a Master Agreement was signed between Japan Asahan Aluminium and the Indonesian government.

In 1976, PT. INALUM, which would lead the construction and running of the project, was established as a company jointly financed by Japan and Indonesia. After that, in October 2013, when the Master Agreement had come to an end, the Japanese capital was transferred to the Indonesian side and PT. INALUM became a completely Indonesian-owned company, which remains to this day.

In 1976, the Indonesian government established the “Asahan Development Authority (ADA)”, a government body related to project construction that supported the entire project by coordinating between government ministries and agencies.

The construction funds for the hydroelectric power plants and aluminium smelting plant were initially estimated at 250 billion yen, but due to subsequent inflation and other factors, the required construction funds were 411 billion yen. The funds raised to finance the project were 91.1 billion yen of personal funds and 319.9 billion yen of loans (Japan Asahan, including JICA and OECF funds: 226.4 billion yen, Indonesian government: 93.5 billion yen).

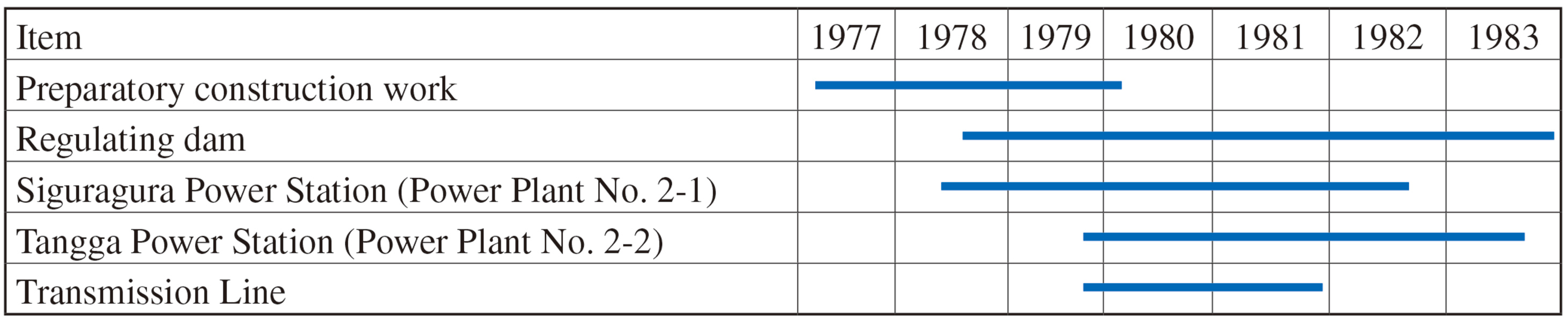

2.3Construction

Of the five power plant plans proposed in the Asahan River comprehensive development plan, Power Plant No. 2 (Siguragura Power Station and Tangga Power Station) were constructed. With regards to Power Plant No. 1, initially, only a regulating dam to regulate the water of Lake Toba was constructed, and the power plant would later be developed as a private sector initiative.

Asahan Power Plant No. 3 is under construction as of 2021 with funding from JICA.

In 1987, the construction of a dormitory for construction workers and the like as well as roads and power facilities to aid the construction work began. At the same time, the contractor for the main construction work was selected.

Nippon Koei was in charge of managing the construction, and young engineers dispatched from ADA worked with Nippon Koei in the design and construction management efforts at the construction sites. Personnel from TEPCO were dispatched as technical advisors to PT. INALUM to support the overall design and construction management of the project.

At the construction sites, initially, there was only a small settlement, and it took about 6 hours to get from the construction sites to the state capital Medan. Also, the communication infrastructure was poor, with Japanese newspapers arriving about half a month after they were published. It was also difficult to purchase food ingredients, and so it is fair to say that the area was reminiscent of a desolate island.

2.4Operation

Power Plant No.2-1 (Siguragura Power Station) was up and running in January 1982, meanwhile, Power Plant No.2-2 (Tangga Power Station) was up and running a year later in January 1983. The total power generation of both power plants is 2,973 GWh/year. This generated electric power helps to produce 225,000 to 250,000 tons of aluminium annually.

3Project Features

3.1Construction

Construction of the furthest upstream regulating dam began in August 1978 and was completed in February 1981. The river improvement work was completed in December 1982. Construction of Siguragura Power Station began in June 1978, with units 1 and 2 up and running in January 1982, followed by unit 3 in April and unit 4 in June of the same year. The construction of Tangga Power Station began in August 1979, with units 1 and 2 up and running in January 1983 and units 3 and 4 up and running in July the same year.

3.2Geology

The geology of the Asahan hydropower project area is a terrain in which tuff, which is ejecta from a huge eruption when Lake Toba was formed, covers the bedrock of paleozoic sandstone. Paleozoic sandstone appears in the headrace tunnels, steel penstock, and power plant facility of Tangga Power Station.

The tuff flows from Lake Toba, causing corrosion and forming deep valleys.

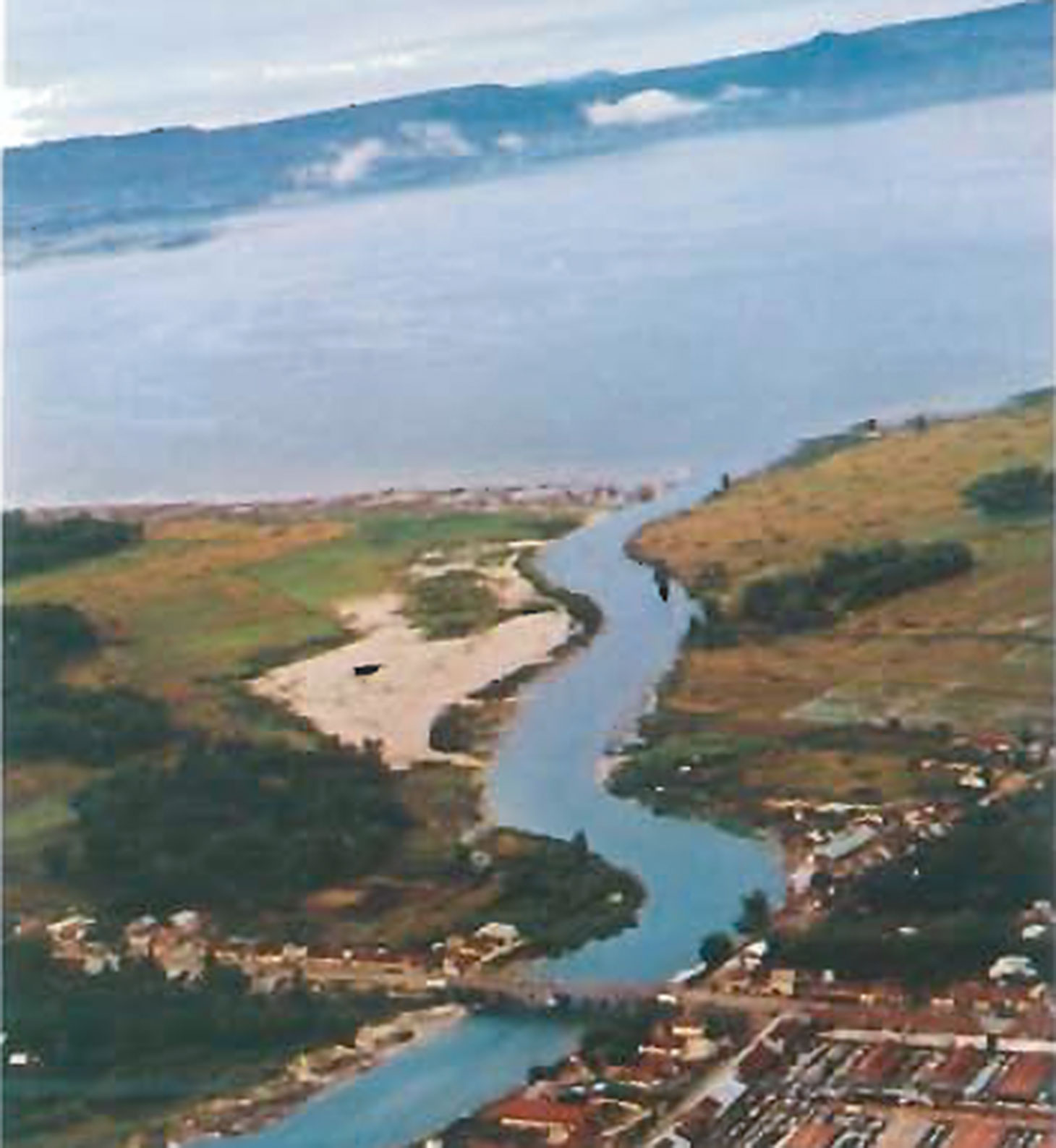

3.3River Improvement and Aggregate Production

The water level of Lake Toba is limited to a high-water level elevation of EL. 905.0 meters and a minimum water level elevation of EL. 902.4 meters to minimize the impact on communities by the lake. In order to maintain these water levels, river improvement was carried out in a section of about 13.5 km from the Lake Toba outlet to the site of the regulating dam. The river was improved by dredging 2.6 million m3 of sediment. Two major tributaries, the Mandoshi River and the Bolon River, flow into the upstream area of this section, and so maintenance dredging is still carried out even after the completion of the construction work.

With regards to aggregate production, the steep bank formed of sandstone on the right side near Tangga Power Station was developed into a quarry to produce aggregate, which was crushed before being supplied to each construction site.

3.4Regulating Dam

A regulating dam was constructed for power generation and to act as the intake dam of Asahan Power Plant No. 1. The point where the Asahan River slowly flows out of Lake Toba and the flow of water changes into a rapid stream was selected as the site of the dam. The dam is a concrete gravity dam 39 meters high and 27,000 m3 in volume.

Power Plant No. 1 was built by an independent power producer (IPP). The scale of the plant is 180 MW, and the generated power is sold to PT. PLN (Indonesian state-owned electric power company).

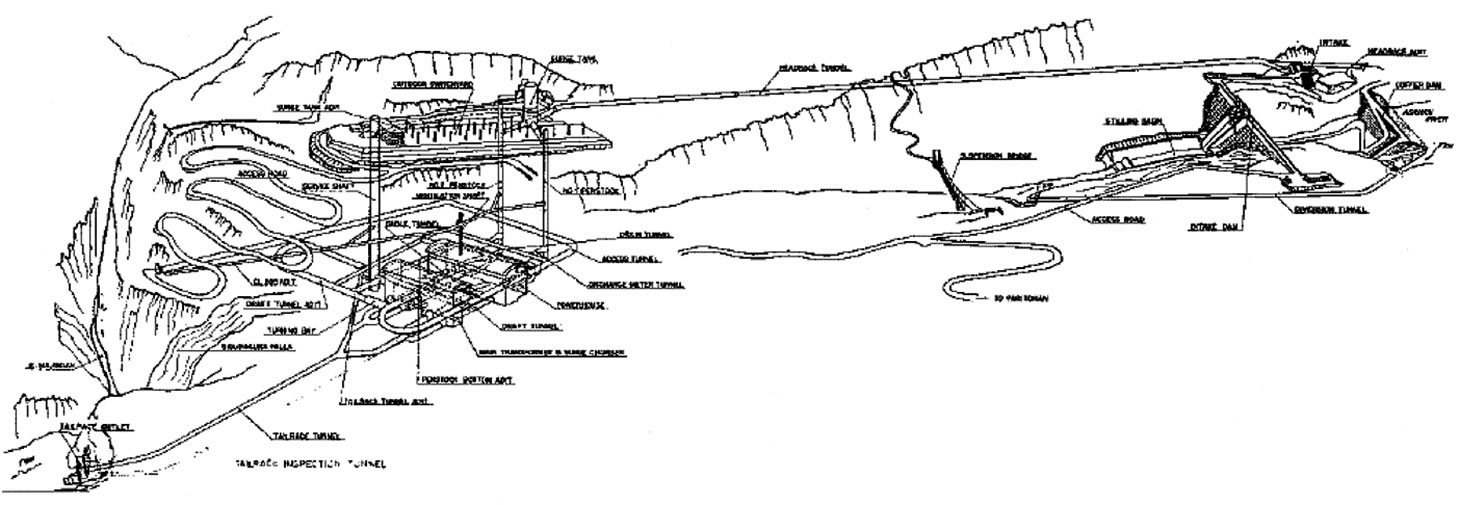

3.5Siguragura Power Station (Power Plant No. 2-1)

Siguragura Dam was constructed at a basin-shaped point about 9 km downstream from the regulating dam. The site has a gentle river gradient and is located about 800 meters upstream of the Siguragura waterfall.

The dam is a concrete gravity dam 46 meters high, 173 meters long, and 38,000 m3 in volume. The water storage capacity is 752,000 m3. The dam is equipped with two spillway gates and one river outlet.

The power plant waterway and power plant facility are located on the bank on the right side of the Asahan River. The power intake is an inclined type with a floodgate and is installed on the reservoir bank on the right-hand side.

The headrace tunnel is a 983 meter-long concrete-lined pressure tunnel with a 6.0 meter-inner diameter. The tailrace tunnel is 359 meters with a 6.1 meter- inner diameter and releases water to the bottom of Siguragura Waterfall, which is also the reservoir of Tangga Dam. As it could not be built on land due to the steep terrain in the surrounding area, the power plant became the first underground power plant in Indonesia. The physical characteristics of the bedrock were measured in a preliminary geological survey, a stability analysis was carried out, and the placement and length of arch lining and prestressed anchors were determined.

The cavity of the underground power plant is 17.9 meters wide, 35.9 meters high, and 79.4 meters long, and adopts a mushroom-shaped cross-section. With regards to the mushroom-shaped cross-section, the arch at the top of the cavity was excavated first, the cavity was stabilized by lining it with concrete, and then the body of the powerhouse was excavated. The tuff at the underground power plant site had not completely cooled following the eruption, and thus work at the power plant excavation site was done under harsh conditions at temperatures close to 40℃.

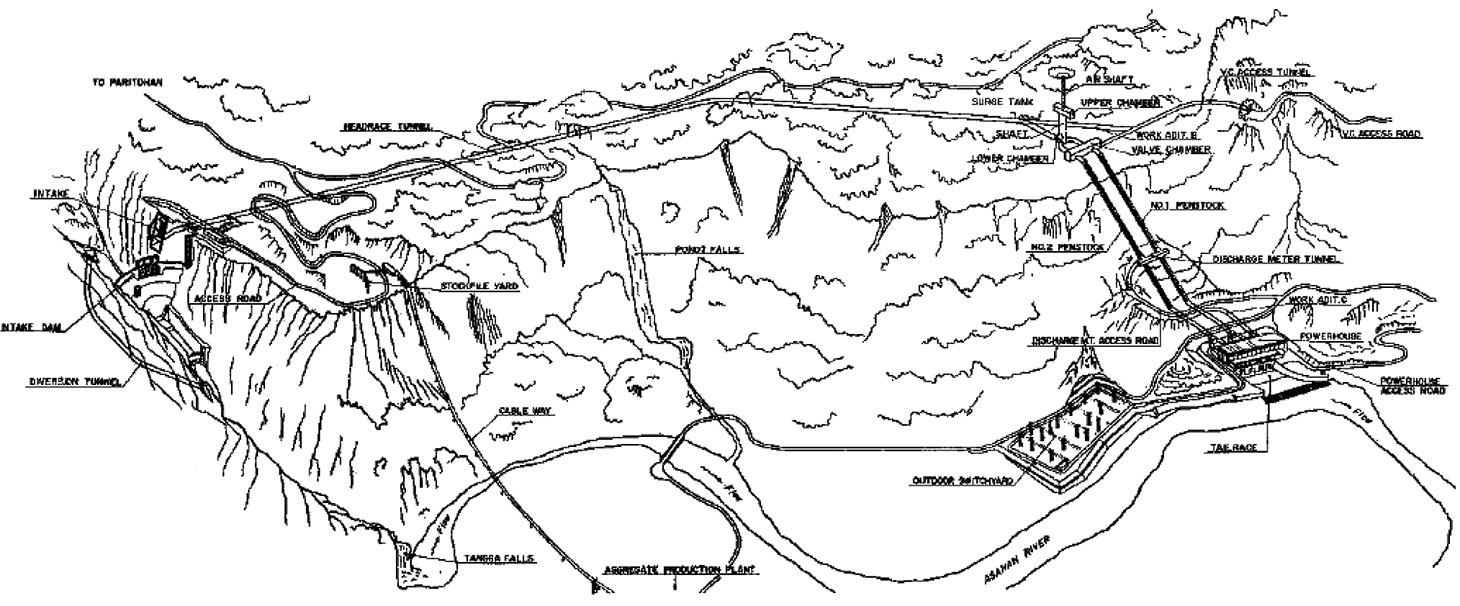

3.6Tangga Power Station (Power Plant No.2-2)

Tangga Dam was constructed 500 meters upstream of Tangga Waterfall where the Siguragura Waterfall leads to the Tangga Waterfall in a 150-meter deep V-shaped valley. It is the only arch dam in Indonesia and is 82 meters high, 125 meters long, and 53,000 m3 in volume. The water storage capacity is 713,000 m3.

Following the construction of the Tangga Arch Dam, the dam would later be used in the design of the Indonesian 100 rupiah bill.

Due to the steep V-shaped valley, the construction road could not reach the top of the dam and could only be built up to approximately 50 meters above top of dam and thus could not reach the top of the dam, which made the construction work a tough task. During the diversion tunnel excavation, the bedrock of the bank on the left-hand side of the exit of the diversion would cause blocks to slide, blocking the Asahan River, and raising the water level. As a result, river water would sometimes flow into the tunnel. Fortunately, nobody was hurt during these incidents.

When starting impounding, in order to avoid a sudden rise in water level, river water would be discharged from the discharge gate at the bottom of the basin, the water level would be adjusted, and efforts would be made to balance the stress of the water pressure of the dam and bedrock. The waterway and power plant facility of Tangga Power Station is located on the bank on the left-hand side of the Asahan River, and the intake is located directly upstream of the dam.

3.7Transmission Line

The transmission line connecting Siguragura Power Station and Tangga Power Station and the aluminium smelting plant is 120 km in length and passes through mountains, palm orchards, and rubber plantation. In addition, there is 10 km of swamp land near the aluminium smelting plant. There are two circuit with a voltage of 275 kV. The transmission towers are 46 meters high on average, with 271 of them in total.

4Lessons Learned

4.1Effective Development of Hydropower Potential

The construction of the Asahan hydroelectric power plants effectively developed the huge power generation potential of Lake Toba and the Asahan River, which are natural assets of Indonesia. The generated electricity is also used for aluminium production. Even now, 38 years after the start of power generation and aluminium production, the power plants are still in operation and the aluminium smelting plant is still in production, making a significant economic and social contribution to Indonesia in the process. Part of the generated power is also used for consumer use through PT. PLN (Indonesian state-owned electric power company), which contributes to the welfare and industrial development of local residents.

At the time of planning and construction, the demand for consumer-use electricity was undeveloped in the region; hence, in order to utilize the area’s huge potential for power generation, the development would be given the green light by proposing to use the generated electricity for the aluminium smelting business, which is an industry that uses a lot of electricity. It is worth noting that although the project uses public funds, the power plants were developed as private power generation for private enterprises.

Power Plant No. 1, which is part of the hydropower potential of the Asahan River, is being used to provide electricity to consumers as a result of private development. Asahan Power Plant No. 3 is also under construction and will supply electrical power for consumer use.

Indonesia has a lot of mountainous areas and a lot of rainfall, meaning it has great potential for generating hydroelectric power. The development of hydropower by the Asahan River can act as a point of reference for other hydropower developments, and while the power plant under construction in Aceh is designed for consumer use, the details of the project are similar to the Asahan hydropower plan.

4.2Contribution to New Jobs

The Asahan Hydropower Project contributes to creating job opportunities for Indonesians through construction and operation. The construction of the power plants was carried out by a joint venture construction company between Japan and Indonesia, and at its peak, 400 Japanese and 5,000 Indonesians were working on the construction. PT. INALUM still employs 2,000 people. Including jobs connected to the project, the initiative has created as many as 10,000 jobs in the region, making a significant contribution to new employment opportunities.

4.3Contribution to the Indonesian Economy and Society

In the area around the hydroelectric power plants, the development and construction of roads and bridges, the development of infrastructure such as hospitals and religious institutions are also gaining traction, and the number of diners and retailers nearby is increasing, contributing to the economic activities and welfare of the local residents.

For a while, PT. INALUM’s performance deteriorated due to the slump in the aluminium market, the appreciation of the yen, and the drop in the water level of Lake Toba, and thus, in 1987 and 1984, reconstruction measures were implemented by increasing the company’s capital. Since around 2003, the business environment has changed for the better due to the aluminium market picking up and the increase in the amount of water in Lake Toba. As a result, PT. INALUM has achieved stable profits, is regarded highly as a company of good standing, and finds itself at the center of mining and refining-related companies. PT. INALUM is also planning to build additional infrastructure as well as develop in other regions.

The construction companies and generator manufacturers that were involved in the construction of PT. INALUM’s aluminium refining business were all top-level Japanese companies; as a result, the very latest technology of the time was adopted for the construction. This project saw Indonesian companies join forces with Japanese companies as a joint venture. By transferring skills through carrying out work such as construction work and equipment installation together, it helped to improve the skills of personnel on the Indonesian side, and these Indonesian companies have since grown into construction companies at the core of the sector. Engineers dispatched from ADA, who was in charge of site design and construction management together with Nippon Koei, would contribute to the development of Indonesia by taking their new skills and experience acquired at the construction sites with them when later holding important positions such as at government agencies, etc.

4.4Consideration for the Environment

Most of the structures in this project were underground structures, with few large-scale excavation works. At the construction sites, there were few local residents in the vicinity and the impact on the relocation of residents and the social and natural environment was limited.

4.5Good Maintenance Management & Operation

The Asahan project was up and running in 1983, and even 38 years later, the infrastructure is well maintained and operations and production remain stable. In 2013, the soundness of the structure and power generation equipment was assessed, and even after 30 years, the structure and power generation equipment were still in good condition and there were no particular problems. This is largely due to the good maintenance and proper operation of PT. INALUM. The power generation equipment is regularly overhauled, and if necessary, equipment is replaced.

PT. INALUM regularly sent maintenance and operation personnel to Japan for training since the days when the construction was ongoing. Now that all the capital has been returned to the Indonesian stakeholders, this training system has ended, but I am confident that if the good maintenance and operation continue, power generation in the area will remain a success for many years to come.

- Figures 2–4, Table 1: 1983 Nippon Koei Asahan Hydroelectric and Aluminium Project “Project Completion Report”.

- Photos 1–6: Used with the permission of Koji Baba.

Asahan Power Plant No. 3 Under Construction

Open Works – Aerial Views

Open Works

Underground Works

Author

Koji Baba

Born in 1950, Baba graduated from Fukushima Technical Institute 1971 and worked for Nippon Koei Co. Ltd,. from 1971 till now.

He worked for Hydro-power Project in overseas mainly including Asahan Hydroelectric Power Project in 1979–1983.