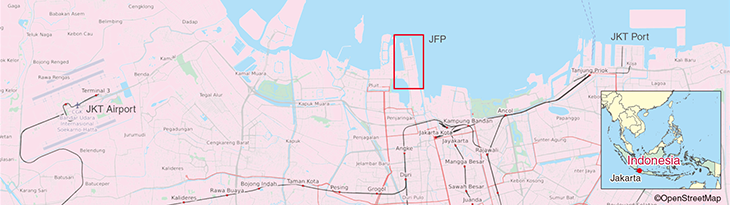

Jakarta Fishing Port Project

In 1973, the Government of the Republic of Indonesia made a request for the Japanese Government to conduct a feasibility study for the development of Jakarta fishing port (JFP) in order to upgrade the fishing industry and improve the livelihood of Indonesian people through fishing and other fishery-related activities. Since that time, the history of the JFP began and the creation of infrastructure and marine facilities were continued for about 40 years up to 2012, facilitated by 6 Japan ODA Loans.

- 1)The whole area of JFP was newly created by land reclamation (80 hectare) and construction of other port facilities, such as quaywalls, breakwaters, revetments and dredging.

- 2)Now JFP is one of the largest fishing ports and fish markets in the world. About 1,500 fishing vessels are registered at JFP and operate in the Indian Ocean, Java Sea, South China Sea, Banda Sea and Arafura Sea.

- 3)More than 100 fishery processing companies operate on JFP premises and export fishery products to Japan, USA, Europe and Asia.

- 4)About 50,000 people work at the JFP complex every day.

- 5)Fish wholesale market in JFP is the fish distribution center to supply fish protein for the greater Jakarta area (about 10 million people).

- 6)Several unique civil engineering challenges were created and implemented under the Project as follows.

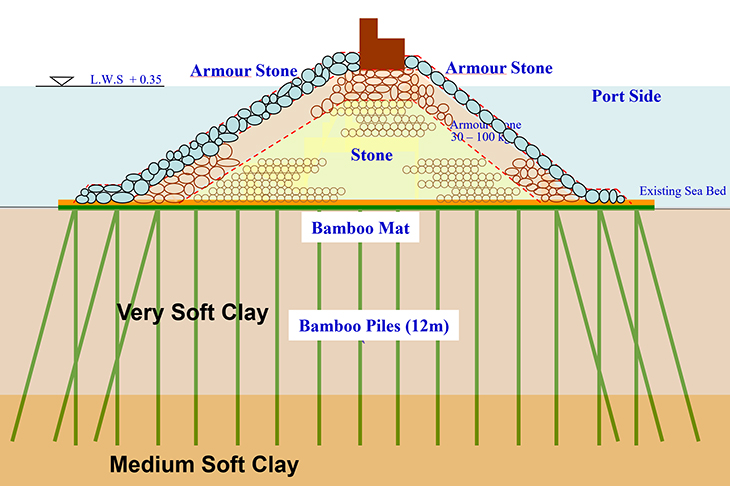

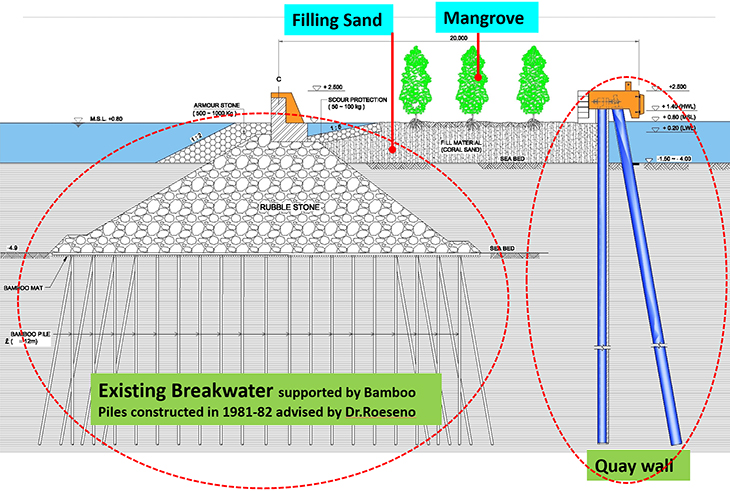

- a. Employment of bamboo piles/mats for the foundation of breakwater and revetment

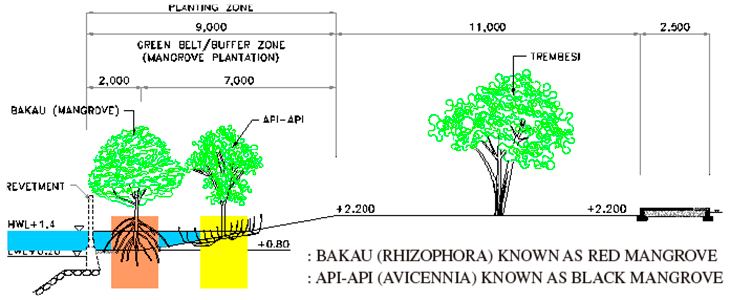

- b. Mangrove forest was employed as a part of function of the revetment and the breakwater

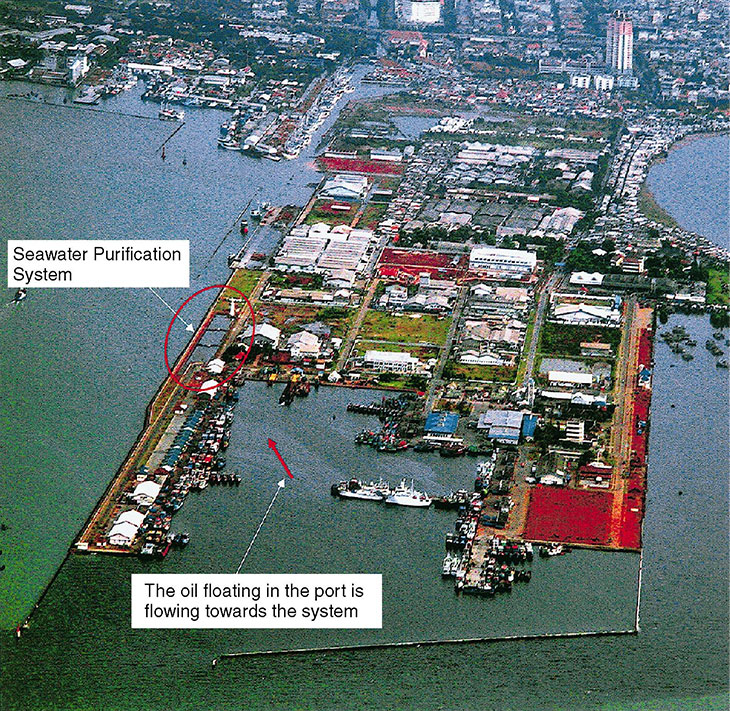

- c. Seawater purification system utilizing the tidal range fluctuation (the Orishimo Method) was created in order to clean the water in the port basin using only natural force without any electric or fuel energy

1Project Background

Indonesia has the world's second longest coastline and the world's third largest exclusive economic zone and is rich in marine fishery resources.

However, about four decades ago, the fishing port and market in Jakarta located at the old Batavia port constructed by Netherlands became outdated and defective due to lack of facilities that could efficiently operate and handle a substantial volume of fishery products. Such difficult and inferior conditions were considered to be the significant factors hampering the development of the Indonesian fishing industry.

In view thereof, in 1973, the Government of the Republic of Indonesia made a request to the Japanese Government to conduct the feasibility study (FS). Overseas Technical Cooperation Agency (OTCA: the former name of Japan International Cooperation Agency (JICA)) conducted FS for the development of fishing port/market in Jakarta in order to upgrade the fishing industry and improve the livelihood of Indonesian people through fishing and other fishery-related activities.

First construction work of the Project was implemented from 1980 to 1984 under a Japan ODA Loan, and the port was opened to the public on July 17, 1984. Improvement and upgrading work was implemented from 1998 to 2001 and rehabilitation work was implemented from 2008 to 2012.

2Project Chronology

2.1Feasibility Study (1973 – 1974)

A team of experts from the OTCA (present JICA) was dispatched by the Japanese Government in 1973. OTCA finalized a report entitled: "The Development Project for the Jakarta Fishing Port/Market" in 1974. The feasibility study report made a detailed description of the project including the location, rated it as a top priority, and gave a firm recommendation on the earliest development. It was envisaged that, when completed, the project would become a model fishing port complex that would not only meet the growing needs for marine products of the Greater Jakarta Area, but would also stimulate the development of the fishing industry in Indonesia.

2.2Engineering Study (1977 – 1979)

First Loan Agreement (L/A) was concluded with the Overseas Economic Cooperation Fund (OECF, present JICA) for the funding of the consulting engineering services of the project in 1977. In 1978, the Directorate General of Fisheries (DGF), the Ministry of Agriculture awarded the execution of the preliminary and detailed design and preparation of implementation program and tender documents to Pacific Consultants International (PCI) of Tokyo, Japan.

During execution of the engineering services, it was determined that the construction works should be divided into two phases (Phase I - Basic Civil Facilities Work and Phase II - Functional Facilities Works). The consulting engineering services were completed in 1979.

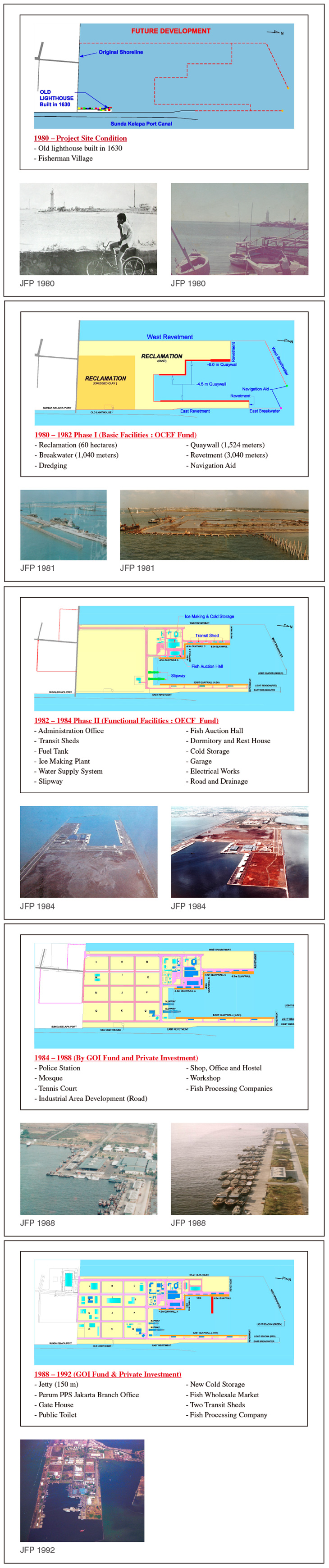

2.3Phase I Construction Works (1980 – 1982)

Second L/A for the funding of Phase I construction works was concluded in 1979.

Rinkai-Sac Joint Operation commenced Phase I works on March 5, 1980 under the supervision of PCI and the works were completed on December 31, 1982.

Phase I construction works consisted of reclamation (60 ha), quaywall (1,524 m), breakwater (1,040 m), revetment (3,040 m), dredging and navigation aids.

2.4Phase II Construction Works (1982 – 1984)

Third L/A for the funding of Phase II construction works was concluded in 1980. Tokai-Wijaya Joint Operation commenced Phase II works on July 4, 1982 under the supervision of PCI, and the works were completed in June 1984.

Phase II construction works consisted of administration office, fish auction hall, cold storage, ice making plant, roads and drainage, water supply, electrical works and other related facilities.

JFP officially opened to the public by President Soeharto on July 17, 1984.

2.5Phase III Master Plan for the Jakarta Fishing Port/Market Development Project (1985 – 1988)

After commencement of public operation in July 1984, the JFP has played an important role in serving fishery activities as well as fishery-related industries. The existence of JFP has given a great boost to trading activities for local and export markets. Fishery-related operations in various fields on JFP premises have become more active year after year. In order to secure and accelerate the different activities, some facilities/subjects need to be urgently upgraded, extended, newly set up, or improved.

In view of the above facts, the Government of Indonesia decided to engage consulting engineering services to review current activities and problems at JFP, and to prepare a master plan for the improvement of JFP by utilizing the balance of the Fourth L/A dated March 1, 1985.

The Master Plan Report was prepared by PCI in December 1988.

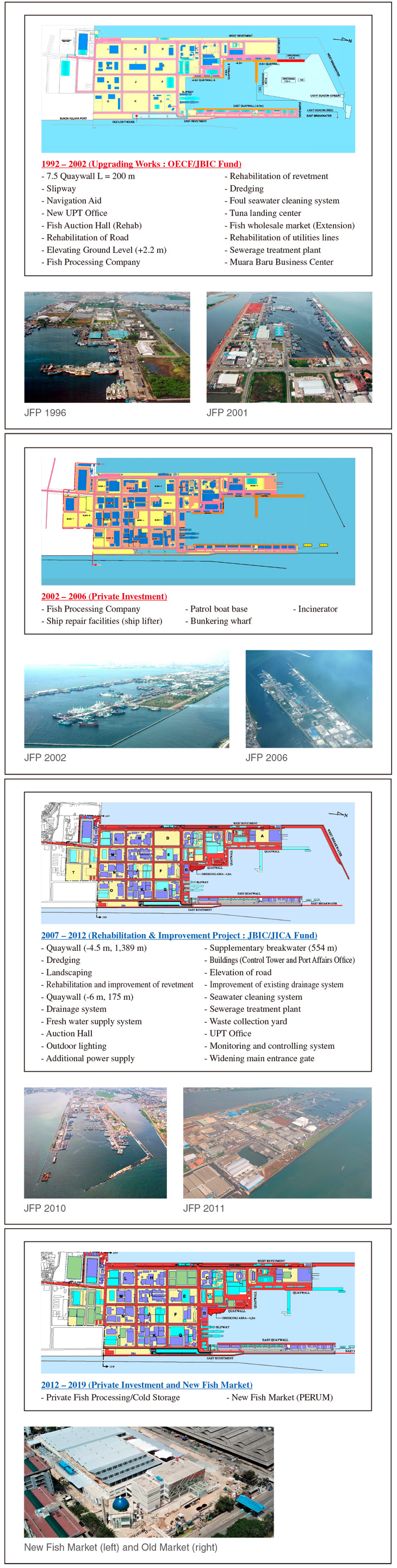

2.6Phase IV Upgrading of Fisheries Infrastructure and Sanitary Facilities (1993 – 2002)

JFP had been in operation for almost ten years. Because of the aging effect and of intense utilization, wear and tear of the infrastructure and functional facilities became apparent. For instance, the sinking of the ground due to land settlement has caused many defects to the infrastructure and functional facilities. It has also negatively impacted the environment. The drainage system hardly serves for outflow of the effluent water, creating patches of foul waters. It was necessary to take overall improvement measures so that the port and market could maintain high international standards of operation efficiency and hygienic conditions, while coping with ever-growing activities of users.

Recognizing the need for immediate improvement and for further upgrades and extension of the existing facilities at JFP, the Fifth L/A was concluded on November 4, 1993 for Phase IV. PCI carried out engineering services for the execution of the preliminary report, detailed design, preparation of an implementation program and tender documents of the project, including supervisory services from 1996 to 2002.

During the implementation of engineering services, it was determined that construction works should be implemented into three packages as follows:

(1) Package I - Sand Filling and Stock Piling Work

In consideration of the settlement phenomena at JFP, it was concluded that sand filling and stock piling work shall commenced first as a preloading in some areas of the JFP. Stockpile material was later used for Package III construction work to elevate the ground level within JFP premises.

PT. Solobhakti Trading & Contractor commenced the works on March 18, 1997, which was completed on April 23, 1998 under the supervision of PCI.

(2) Package II - Port Facilities and Package III - Land Civil, Buildings and Utilities Works

During the implementation of engineering studies, it was determined that construction works for Package II and III would be carried out simultaneously.

The general description of the works is enumerated hereunder.

Package II: Port Facilities

- Construction of quaywall with -7.5m water depth

- Dredging

- Ship repairing facilities

- Foul sea water purification system

- Rehabilitation of revetment/breakwater

- Installation of utility works (electrical and water supply facilities) on the quaywall

Package III: Land Civil, Building and Utilities Work

- Upgrading of ground elevation up to +2.20 m

- Renovation of existing auction hall

- Construction of UPT administration office

- Renovation of the port affairs office

- Rehabilitation of wholesale market

- Construction of tuna landing center

- Construction of Muara Baru Center (shopping/offices/canteen complex)

- Renovation of roads and drainage system

- Rehabilitation of the existing electric power supply

- Improvement of the water supply system

- Improvement of the seawater intake system

- Construction of sewerage treatment system

- Other supporting facilities such as public toilets, musholla and canteens

- Sodding and planting trees

Rinkai-Hutama Joint Operation for Package II works and Waskita-Daito Joint Operation for Package III works started on August 12, 1998 under the supervision of PCI.

The construction works were completed on February 28, 2001 for Package II, and on October 31, 2002 for Package III.

2.7Rehabilitation and Improvement Project of Jakarta Fishing Port (2004 – 2012)

The -4.5 m RC pile supported quaywall structure (total length = 1349 m) was constructed in 1982 under Phase I. In general these structures are in good condition, but in 1996 it was found during the Phase IV engineering study, that settlement occurred for a period of 20 years due to excessive deep underground water pumping in Jakarta City for the fresh water supply. The deck apron elevation at the berthing side now is about +1.34 – 1.62 m above LLWL elev.0.00, which was designed and constructed for +2.00 m in 1982 considering HWL +1.40 m + allowance 0.6 m. As a result of the settlement, elevating work of the quaywall is urgently required, since the sea level has been recorded at or above the height of the quaywall at high tides.

Average settlement rates from 1976 until 1996 was about 2.0 cm per year. Average deck elevation would thus become +1.20 in 2010 and +1.0 in 2017, if settlement continued at the same rate. Such circumstances would cause serious flooding on the quaywall deck, hampering fish landing activities and loading water, ice, fuel, foods, etc.

In addition to the quaywall, it was also necessary to reinforce breakwaters to maintain the calmer port basin. And some countermeasures and management consulting services to maintain the Jakarta Fishing Port "Clean and Hygienic" and better Operation/Management are required.

Traffic to and from JFP increased in those days and the only access road became very congested. It was necessary to rehabilitate the road for a smooth and safe approach to the port.

Under such circumstances, the Directorate General of Capture Fisheries (DGCF), Ministry of Marine Affairs and Fisheries decided to implement rehabilitation work of the quaywall and other countermeasures for the improvement of fishing port operations. The Sixth L/A was concluded between Japan Bank for International Cooperation (JBIC, present JICA) and DGCF on March 31, 2004 for the Project.

PCI commenced the consulting services on December 16, 2005 and carried out the execution of the preliminary report, detailed design, preparation of implementation program and tender documents of the project, including Supervisory Services.

During implementation of the consulting services, it was determined that construction works should be implemented into three packages as follows:

(1) Package I: Port Facilities

- Quaywall with -4.5 m water depth

- Supplementary breakwater (mangrove breakwater)

- Dredging

- Building (Control Tower and Port Affair Office)

- Landscaping

TOA-PP Joint Operation commenced the Works on December 20, 2008 and were completed on December 19, 2010 under the supervision of Oriental Consultants (OC, ex. PCI).

(2) Package II: Road, Drainage and Revetment Improvement of JFP

- Elevation of road

- Rehabilitation and improvement of revetment.

- Improvement of existing drainage system.

PT. Hutama Karya (Persero) commenced the Works on March 20, 2009 under the supervision of OC and were completed on November 15, 2009.

(3) Package III: Quaywall, Building and Road (Additional Works)

- Quaywall

- Seawater cleaning system

- Road rehabilitation

- Drainage system

- Sewerage treatment plant

- Auction hall

- UPT's office

- Other facilities

TOA-PP Joint Operation commenced the works on September 7, 2011 under the supervision of OC and were completed on July 8, 2012.

2.8Development History Illustrations

In addition to the above description on the chronology of the Project, the following figures may be useful in clearly understanding the development history of the JFP.

3Project Features

3.1Role of the Jakarta Fishing Port

Since the commencement of public operations in July 1984, JFP has been one of the primary ports to dominate the fisheries industry throughout the Indonesian archipelago in terms of its annual fisheries production for export and local consumption. It was constructed as an environment-friendly fishing port providing modern facilities fully capable of accommodating and servicing ocean-going fishing vessels and/or refrigerated fish carrier vessels in international trade, as well as handling high-value and quality fish for export marketing.

In particular, JFP serves not only as a fishing port, but also as the largest fish marketing and distribution center for domestic wholesale trading. It also serves as a center for processing fish, shrimp and other marine products for export. The port plays an important role in exporting as an origin point for frozen fish and processed seafood shipped in refrigerated containers or by refrigerated carrier vessel, and for fresh fish air-freighted to overseas destinations with high quality HACCP international standards.

The four main guiding principles for the JFP are below:

(1) Keep JFP clean and hygienic.

(2) Give fair and equal opportunity and benefit to every JFP user utilizing its facilities and services.

(3) Exert full control over ship movement in port; and

(4) Provide ample services that meet the varying needs of JFP users, irrespective of the recipient being a small-holder or an entrepreneur.

Since the completion of the latest Japanese ODA Project in 2012, there have been remarkable changes in the nature and volume of processing and trading conducted in the fishing port complex. First and foremost is the increase in the volume of fish and processed products handled at JFP due to the rising demand of fish processing factories targeting international markets for export. A great number of new players in the fishery business have invested and built factories in JFP.

Although JFP is in its optimum utilization and fully supports the ever growing fishery activities in Indonesia, there still remain defects from ground settlement and wear and tear of some facilities constructed under past projects. These defects disrupt the smooth and effective operation for handling of fish at JFP and need to be addressed immediately.

3.2Unique Civil Engineering Challenges

Unique civil engineering challenges were made under the Project as follows.

- a. Employment of bamboo piles/mats for breakwater and revetment foundation

- b. Employment of mangrove forest as a part of wave reduction function of the revetment and the breakwater

- c. Seawater purification system utilizing the tidal range fluctuation (the Orishimo Method)

3.2.1Bamboo Piles and Mat Foundation

Considering the very soft subsoil conditions in JFP area, a bamboo pile and mat foundation system was employed in order to distribute stone load uniformly by bamboo mat and to reduce the load by friction of piles. Although the breakwater and the revetment planned in JFP were about 4,000 m in total, construction costs were lower by utilizing local materials and sufficient local manpower.

Since the JFP project provided the technical feasibility of employment of bamboo piles and mat foundation for breakwater and revetment structures, the same method was applied to breakwater for Jakarta Tanjung Priok port, and breakwater and revetment for Patimban Port under Japan ODA loans.

3.2.2Mangrove Breakwater and Revetment

Indonesia has one of the world’s largest mangrove forests. To reduce wave attack by breakwater or revetment, a combination of concrete parapet and mangrove as illustrated below is very effective and reduces construction costs. Usually a breakwater or revetment is designed to stop overtopping of waves. However, wave overtopping can be allowed by utilizing mangroves behind hard structures. Mangroves can absorb completely overtopped waves and stop waves before reaching the backside area. Lowering top elevation of breakwater or revetment reduces construction costs. In addition to cost performance, the method has a positive effect on the environment by providing a green landscape and by protecting the land from salty wind invasion.

Mangrove communities were developed along the western side of the revetment through a natural process (Api-Api) generating from the adjacent area called Pantai Mutiara. Bakau were also planted.

Special attention was given to the sea level behavior and tidal fluctuations within the area to form a suitable natural ground slope along the west revetment, to act as an interface between land and sea. The primary factors to determine the required level for growing of mangroves in accordance with species requirements and tidal range where it naturally grows is illustrated below.

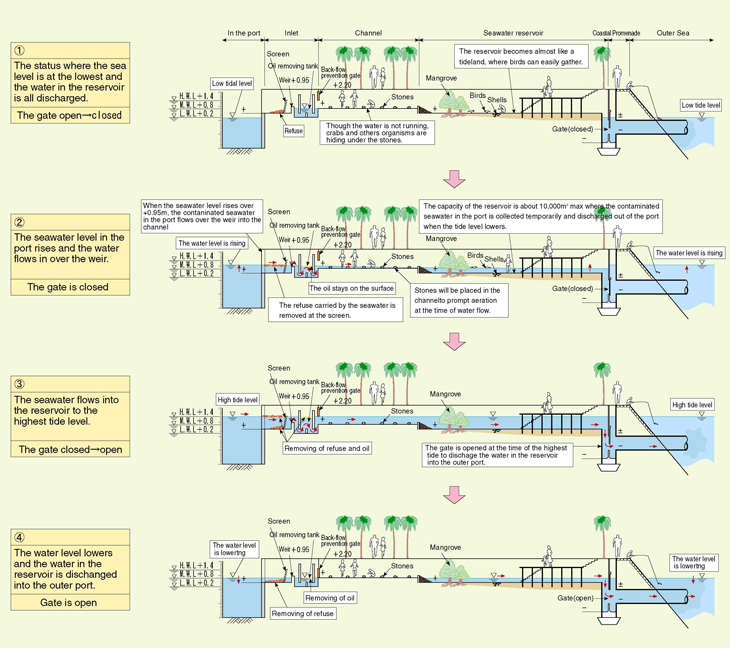

3.2.3Seawater Purification System Utilizing the Tidal Range Fluctuations (the Orishimo Method)

As the JFP was constructed in the Jakarta Bay, with a shoal extending for a considerable distance from the shore (the seabed grade of 1 in 300), the port is surrounded by breakwaters (occupying about 40 ha, of sea area having average water depth of about 5 m). The tidal range fluctuation is usually only about 60 cm and the natural exchange of the seawater in the port is small. Moreover, around 300 ships use the quaywall for mooring, frequently with more than 3,000 fishermen living on board the ships. Since wastewater is disposed from the fishing vessels directly into the basin including waste oil by leakage coming from the vessels, water pollution in the port basin is becoming worse. During the Phase IV engineering stage, it was proposed by the consultant to construct a device for seawater exchange / purification system in order to overcome water pollution in the port basin in relation to tidal fluctuation, site conditions and environmental aspects.

Engineering Conception of the Seawater Purification System in the Port Basin

The seawater purification system was required to meet the following criteria and conditions:

- To accelerate the exchange of about 2 million m3 seawater in the port

- To be able to remove floating garbage and waste oil during seawater exchange process

- Easy operation and reduced maintenance costs

- To clean the polluted seawater as much as possible before discharging outside the port basin

- To enlighten and educate citizens about the seawater pollution issue

- To beautify the environment as part of the fishing port complex

A detailed report of this unique seawater purification system, which was published by the Overseas Report of the JSCE Monthly Journal (October 2003), is attached as an Appendix of this Archive.

4Lessons Learned

4.1Continuous involvement of engineers during project period

As ODA projects like JFP take a long time to execute and for the intended results to materialize, it's important that an engineer or a team of engineers be engaged in the project as long as possible.

In the case of JFP, Oriental Consultants Global (ex. Pacific Consultants International) was continuously engaged in the project, and it resulted in continuous engagement of a consultant, Mr. Sadao Orishimo.

He worked for the project not only in the stage of designing but also in the stage of construction supervision.

He observed what went on the project site, had time to review the contracted drawings, and had chances to improve or amend the original design.

For example, the seawater cleaning system and the mangrove revetment were much improved during the supervisory services.

4.2Importance of Understanding Local Conditions and Natural Environment

There are sets of design standards or manuals for civil engineering in Japan. However, the important thing is how to adjust such standards/manuals to suit the local conditions and the natural environment when implementing overseas projects.

For the JFP project, the following new methods were developed and employed considering local conditions/the natural environment, and cost performance. By monitoring the impacts of these methods in the long term, new standards or manuals can be developed for future project in Indonesia or similar nations.

- Bamboo pile/mat foundation for revetment and breakwater

- Seawater purification system utilizing the tidal range fluctuation (the Orishimo Method)

- Employment of mangrove forest as a part of function of the revetment and the breakwater

4.3Transfer of Technology

Since sufficient engineers or skilled staff were not available in Indonesia in 1978, when JFP was started, the Japanese consultants conducted field surveys and investigations using their own Japanese staffs. Then the consultant prepared the preliminary report in Japan and explained and discussed the conclusion with the Indonesian side. Based on the agreed scope and design, the final report also was prepared in Japan.

However, during the construction periods, Mr. Soekirno, the Client Project Director, decided to employ civil engineers, mechanical engineers, and economic/financial experts who just graduated from the University of Indonesia. They had worked with the consultant during the construction stages, so they became very familiar with the project components and obtained plenty of knowledges about the facilities constructed and installed during the project. After the completion of the project, they were assigned as either operation engineers or management staff of JFP. Through this method, proper operation and maintenance of JFP was conducted very smoothly.

In addition, a number of engineers and staff were dispatched to Japan to learn about fishing port operation and management under the Project scheme. There they obtained knowledge about how to keep JFP clean and hygienic and to manage JFP properly.

4.4Efforts to Spread Awareness of the Project to the Indonesian and Japanese people

4.4.1Study Tour of the Project

Through the project implementation, it is very important to provide opportunities for people to visit the project site. Since 2003, JFP has received an annual study tour from Jakarta Japanese School, so until present more than 2,000 primary school children have learned about fisheries activities, port facilities, ice plant, cold storage (-35℃), environment considerations (seawater cleaning system and mangrove planting) and the ODA scheme at JFP. In addition, the students from various universities and high schools of Japan and Indonesia have visited JFP to study the project history and performance and many Japanese living in Indonesia have had the experience of learning about Japan's ODA project at JFP.

4.4.2Establishment of a Library of the Project

Jakarta Fishing Port Project is one of the Japan's longest running ODA projects. In order to properly store various important reports/information from the beginning in 1973, a historical library was established on the 4th Floor of UPT (Administration office) at JFP. Everyone can see and access the materials at any time.

4.4.3Publication of the Historical Record of the Project

In order to precisely record and introduce the long history project, a book titled "History of the Jakarta Fishing Port ∼ records of 40 years events" was published for the public in 2014 as a Japanese version supported by JICA. Additional information which was not included in the book can be found at the following JICA website.

[external link] https://libportal.jica.go.jp/library/public/ProjectHistory/jakarta/jakarta-p.htmlUnique seawater cleaning system created by this project was employed as a text for the students of civil engineering of University of Indonesia and they sometimes visited the project site to understand the system.

1961-1999: Overseas Economic Cooperation Fund (OECF)

1999-2008: Japan Bank for International Cooperation (JBIC)

2008-Present: Japan International Cooperation Agency (JICA)

Appendix

This article is reprinted from the Civil Engineering, JSCE, Vol.41, pp.75-80, 2004.

OVERSEAS REPORT

Seawater Purification System Utilizing the Tidal Range Fluctuation: A Unique Engineering Challenge at the Jakarta Fishing Port

Sadao ORISHIMO

Pacific Consultants International

The Outline of the Jakarta Fishing Port

Indonesia is the world's third largest maritime nation after the USA and Australia, possessing 5.41 million km2, i.e. 200 nautical miles of Exclusive Economic Zone (EEZ). In 2000, it became the world’s 6th nation in fisheries sector, producing approximately 4.93 million tons of fish. Of the total fish production, 4.14 million tons or approximately 84% depends on the marine fisheries. However, due to the insufficiency of the fisheries infrastructure development and modernization of the fishing boats, a sustainable marine fish resources management system has not yet been established. Under such circumstances, in 1999, President Abdurrahman Wahid reorganized the Directorate General of Fisheries that had been under the Ministry of Agriculture into the Ministry of Marine Affairs and Fisheries in order to place emphasis on the sustainable development of the marine fishery resources.

In 1973 the Government of the Republic of Indonesia requested the Japanese Government to conduct a feasibility study for the development of a fishing port/market in Jakarta to upgrade its fishing industry. The Overseas Technical Cooperation Agency (OTCA: presently Japan International Cooperation Agency (JICA)) responded and conducted a feasibility study for the construction of a new Jakarta Fishing Port/Market. That is when the history of the Jakarta Fishing Port (JFP) (Photo-1) began. JFP was completed in 1984 with yen-loans from Japanese Overseas Economic Cooperation Fund (OECF: the predecessor of the present Japan Bank for International Cooperation) and started its service as the largest fishing port in Indonesia. The author has been involved in this project since 1978 and is still working as the chief consultant. In Phase I: Port Facilities Construction works, locally traditional bamboo piles and bamboo mats were used to build the foundation of 4,000 m long coastal revetment and breakwater in order to cope with the soft seabed condition (JSCE Journal; March 1986.)

The original plan for JFP was to integrate small-scale fish landing places around Jakarta and to make JFP the fishery center in the Java Sea. However, trawl fishing in the Java Sea was completely banned in the beginning of 1980, and the fishing ground was expanded as far off as the Madura Island, the Natuna Sea area and the Indian Ocean off Sumatra.

During the latter half of 1980, in addition to its function as the supply base for marine products to Jakarta citizens, JFP became known as the base for fresh tuna landing from the Indian Ocean and the daily airfreight exportation for the sashimi market. This business became very active partly because of the strong yen and the increasing number of airline flights to Japan from Jakarta. At present, about 20% of the fresh tuna airlifted to Japan from overseas is from Indonesia. Fishery products transported from various places nationwide are traded during nighttime at the Jakarta Fish Wholesale Market located inside JFP complex where more than 10,000 people in the fishery business related work carry out their transactions. More than 80 companies engaged in fish processing activities have been operating their factories in JFP covering about 30 ha of land area of JFP with more than 10,000 employees. JFP is now the processing center of shrimp and fish, contributing to the export of fishery products in Indonesia as well as local market. At present, the JFP has grown to be a fishing town where almost 30,000 people are working everyday from early morning to midnight. The value of fish transaction amounts to approximately 100 million yen on-site every day.

The JFP provides three functions: A fishing port, a fish distribution center and fish-processing center. Moreover, in the Phase IV project, a "1,500 meter-long coastal promenade along the east coast" and a "unique mangrove revetment on the west coast" have been constructed, providing beach recreation spots for citizens who enjoy fishing and strolling along the waterfront. The JFP has been specially noted by the Japanese government for the following reasons: 1) It is one of the typical and pioneer Japanese ODA projects based on the "technical cooperation by JICA" and the "JBIC's yen loan"; 2) The redevelopment projects considering the environment are continuously implemented, and 3) It is well popularized in the district and used by the local fishermen and citizens. With the above reasons, together with the fact that it is well placed in the city of Jakarta, the JFP has been attracting to private investors and a lot of visitors from both within the nation and abroad coming to JFP.

The present state of the sea area of the fishing port

As the JFP was constructed in the Jakarta Bay, with a shoal extending for a considerable distance from the shore (the seabed grade of 1 in 300), the port is surrounded by the breakwaters (occupying about 40 ha, of sea area having average water depth of about 5 m) is exclusive. The tidal range fluctuation is usually only about 60 cm and the natural exchange of the seawater in the port cannot be expected much. Moreover, around 300 ships are using the quaywall for mooring frequently with more than 3,000 fishermen are living on board the ships. Since wastewater from the fishing vessels are disposed directly in the basin including waste oil by leakage coming from the vessels, the pollution of the water in the port basin is becoming worse and worse. During the Phase IV engineering stage, it was decided by the author and his colleagues to construct a device for seawater exchange / purification system in order to overcome the water pollution in the port basin that will be applicable in relation to tidal fluctuation, site condition and environmental aspects point of view.

Engineering conception of the seawater purification system in the port basin

The seawater purification system was required to meet the following criteria and conditions:

- To accelerate the exchange of about 2 million m3 seawater in the port.

- To be able to remove floating garbage and waste oil during seawater exchange process.

- Easy operation and less maintenance cost.

- To clean the polluted seawater as much as possible before discharging outside the port basin.

- To enlighten and educate the citizens about the seawater pollution issue.

- To beautify the environment as part of the fishing port complex

It is a common idea in Japan to discharge the seawater using a large pump and floating garbage by a refuse collecting ship. However, in a developing country like Indonesia, and in a fishing port, which generate small profit, the possibilities of using machine type system will be difficult and expensive to operate and maintain. For several years, the author has been searching for a device that would fulfill the criteria and conditions as mentioned above.

While taking a bath at home, the author observed the grimes being washed away as the hot water in the bathtub overflowed. Observing this phenomenon, the author came to a revelation that it might be possible to recreate this phenomenon using the daily rise and fall of the tide. Having arrived at this idea, the author has assembled the prerequisites that must be met to realize this idea as follows:

- A system that naturally overflows the seawater.

- In order for the seawater to overflow, the place must be a lower place than the sea surface.

- A reservoir that is large enough to temporarily collect the overflowed water from the port.

- To be able to maintain the condition of temporary emptiness of the reservoir.

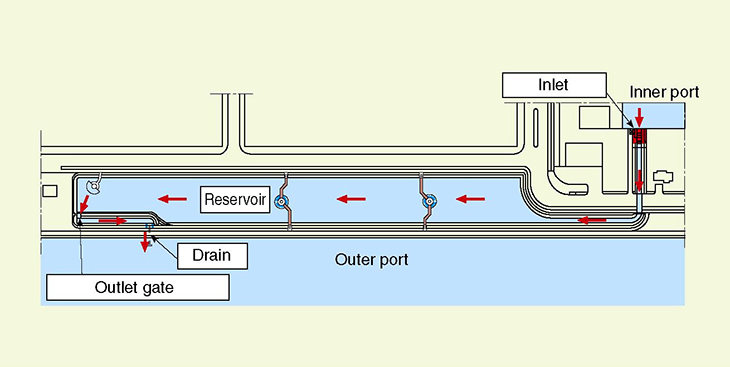

In order to meet the above conditions, the author and his colleagues have decided to construct as large a reservoir as possible. The conceptual plan of the water purification system of the port was created as shown in Fig.1. The outline of the system is as follows:

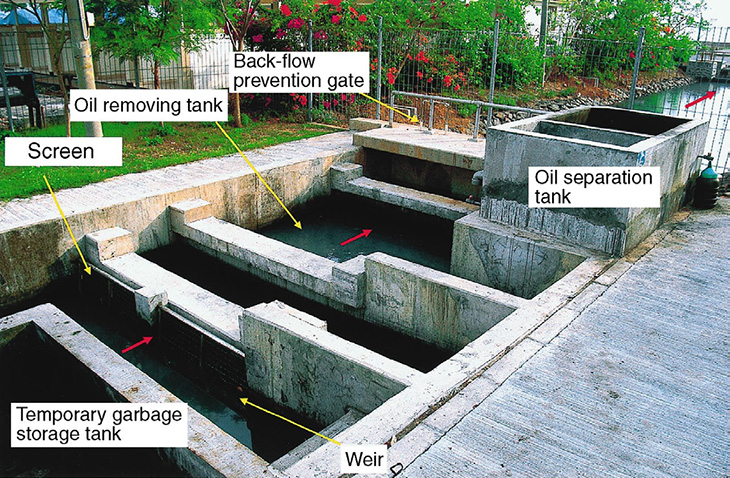

- Construct a reservoir, which is large enough (approx.10,000 m2), and make its basin as low as possible. (Photo-2) in order to make the capacity as large as possible (max. 10,000 m3 at the time of spring tide, average 4,000 m3).

- Install a gate to discharge the reservoir water out of the port, so as not to let the outer seawater in by opening/closing the gate. To install a screen in front of the gate to prevent the refuse from the reservoir from flowing out of the port.

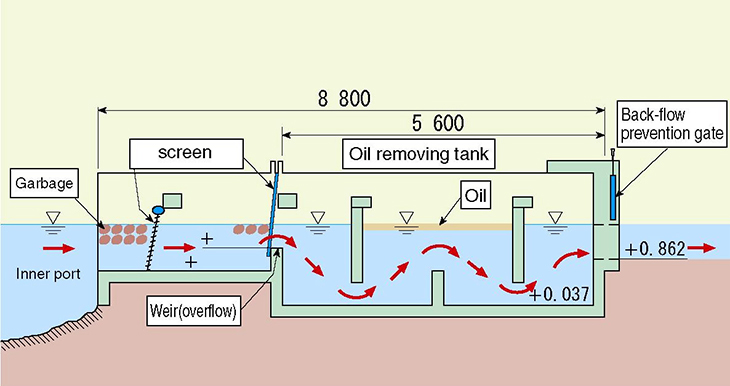

- Install a device to take in the seawater in the port ("inlet" hereunder) at the innermost area of the port. (Fig.2, Photo-3)

- Construct a weir in the inlet in order for the seawater in the port to overflow into the empty reservoir when the tidal level rises over the weir height. (Fig.-3)

- Install a screen in the inlet in order to prevent the floating refuse/garbage in the port from flowing into the reservoir. (Photo-4)

- Since the oil easily floats on the inlet water, an oil-removing tank should be installed to prevent the oil from flowing into the reservoir.

- Install a gate at the inlet in order to prevent the seawater that had flowed into the reservoir from going back to the port during ebb tides.

- Create a channel made of natural stones extending from the inlet to the reservoir to prompt aeration at the time of the seawater inflow and create an environment in which sea habitats such as fishes, crabs and others organisms can thrive. (Photo-5)

- Plant mangroves in the reservoir to create a seawater purification system by zooplankton and phytoplankton mechanism of mangrove characteristics. (Photo-6)

- Create a tideland in the reservoir in order to prompt purification functions by shells.

- Plant enough vegetation around the channel and the reservoir to create a beautiful landscape (Photo-6). Also, build wooden bridges and terraces as resting spots for people.

Conclusion

The construction works have been completed and the testing of the seawater purification system has been carried out. As a result, the following points have been found out.

- The seawater in the port is overflowed over the weir at the flux time as had been expected. Although the inflow amount differs depending on the tidal level of the day, the maximum is 10,000 m3/day and the average is 4,000 m3/day. Since the water amount in the port is approx. 2 million m3, about 0.2% of the water in the port is discharged every day.

- It was confirmed that the floating refuse such as plastic bottles, plastic bags and wooden pieces could be completely removed when the seawater in the port flowed over the weir and through the screen. This has proved that the inlet had a better refuse collection function than had been expected. If the refuse caught at the screen fails to be removed, the screen promptly gets blocked up with the refuse and the seawater's overflowing power at the weir deteriorates. It is important that the people in charge continuously remove the refuse at the time of the seawater overflow.

- The oil and other matters floating in the port flows into the inlet, as are clearly recognized in Photo-l. The oil floats in the oil-removing tank and can be easily disposed of.

- The seawater from which the refuse and oil were removed is more transparent than expected.

- The revetments of the channel and the reservoir made of natural stones are environments where algae grow easily and fish and other organisms can breed, providing a good fishing spot. Also, they create a pleasant space in a fishing port, abundant in greenery.

- Mangroves are in midst of their growth.

- The oldest lighthouse in Indonesia was maintained in the reservoir, which provides a landscape that is in harmony with the historical heritage.

Thus this "seawater purification system" has proved to fully function as designed. However, since the timely opening/closing of the gate according to the tidal level and removing of the refuse and the oil have to be executed by man, whether this system will perform according to the designed functions continuously totally depends on the operator's will and passion.

At the time this article was written, as part of the industrial wastewater was still flowing into the reservoir, the degree of purity of the seawater in the port was not measured quantitatively. It is our future goal to measure the water quality periodically (levels of COD, nitrogen, phosphate, etc.) and assess the effects of the system quantitatively.

Lastly, in introducing this system, I would like to express my sincere gratitude to Mr. Sadayuki Oka, Fisheries Agency (JICA Fishery Expert at that time), who gave me precious advices; to Mr. Nobuo Hazeyama, Chief Representative of JBIC Jakarta at that time; to Mr. Hideki Wakabayashi at the Japanese Embassy; and to Mr. Toshiro Matsushima at Rinkai Construction, who has been involved in this construction project.

Author

Sadao Orishimo

Born in 1948, Graduated from Tokyo Metropolitan University in 1972, Worked for Pacific Consultants International (PCI) 1971-2008 and Oriental Consultants Global (OCG) 2008-Present.