|

During the past decade, a wide variety of Fiber Reinforced Concretes (FRC) have been developed,

including high performance fiber reinforced composites such as SHCC, UHPFRC and so forth.

This committee was established to promote structural applications of FRC, and it prepared a

state-of-the-art report covering the following items:

Structural design of FRC structures (WG1)

Durability design of FRC structures (WG2)

Testing methods for FRC (WG3)

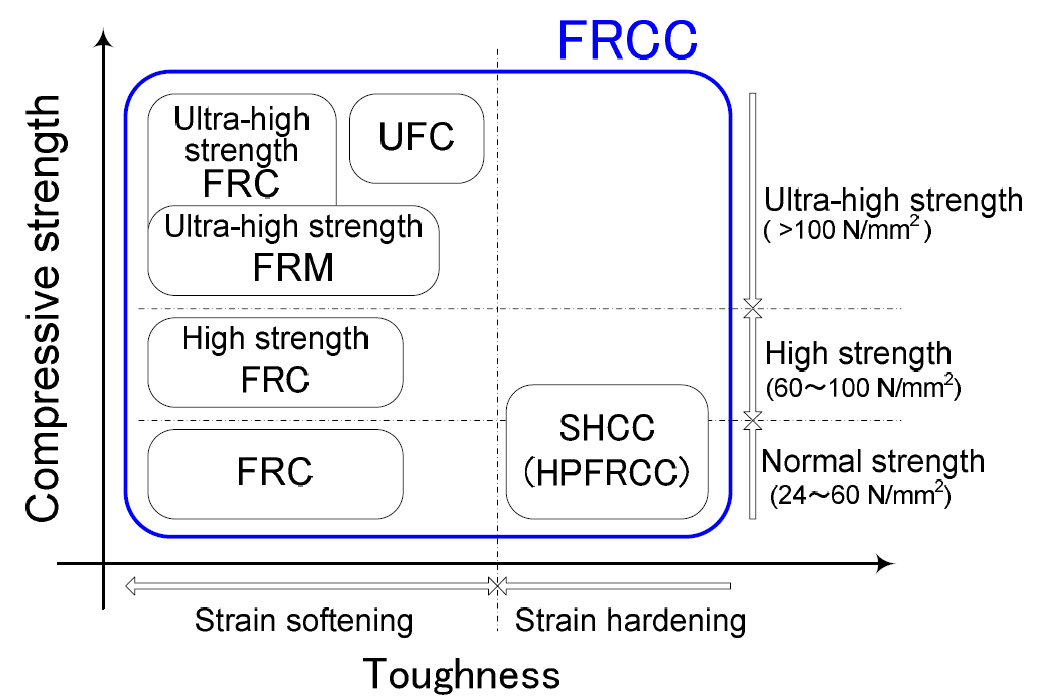

Figure 1 Proposed classification of FRC

Structural design of FRC structures

In this part of the report, the following items were discussed.

(1) A wide variety of FRC and their structural designs (compositions, material properties, design values, etc.)

(2) Advantages of FRC (flexural strengthening, shear strengthening, crack width control, etc.)

(3) Influence of construction method on the mechanical properties of FRC

In this sub-committee, the materials were classified in terms of compressive strength and material

toughness, as shown in Figure 1. In addition, design code for each material category was proposed.

It seems that there is specific gap between each category in the schematic image, but the physical

phenomenon should be seamless. Further discussions are needed.

To establish a design code for FRC structures, it is important to clarify the effect of construction

method on the mechanical properties of FRC (i.e., significant fiber orientation and heterogeneity

can be observed in the case of flowable FRC). To overcome the above issue, a method for

controlling fiber orientation during construction and a strengthening system to improve the

heterogeneity of the cast FRC should be proposed, including reasonable safety factors in design

code that reflect fiber orientation.

Figure 2 Observed fiber orientation in 100×100×400mm beam specimen

Durability

In this part of the report, the following items were discussed.

(1) Establishment of a durability design code

(2) Durability of the bond (fiber/matrix) in FRC

(3) Collecting back data on the durability of FRC

In this sub-committee, the materials were classified in terms of compressive strength and material

In the JSCE standard specifications for ordinary concrete, verification of corrosion-induced damage

is carried out based on the limit amount of Cl- ion at the rebar location. There is no advantage for

FRC in this verification method. A new approach includeing the crack closure function of FRC

should be proposed.

In addition, back data on the durability of FRC, including “fatigue of cracked FRC” and

“deterioration of the synthetic fiber itself,” should be collected.

Testing Method

In this part of the report, various types of developed testing methods were examined. Each testing

method was classified into three categories: for ordinary FRC (normal strength, strain softening),

UHPFRC (UFC) (ultra high strength, strain softening) and SHCC (normal strength, strain

hardening).

The proposed testing method should be directly linked to a verification method in the design stage.

From this viewpoint, testing methods for structural performances such as tensile, bending and

compressive strengths were proposed. There is, however, no testing method to verify the durability

of FRC structures at this time.

As mentioned in the above section, the mechanical properties of FRC are strongly affected by the

fiber orientation and distribution. Testing methods for the heterogeneity of FRC before and after

hardening is thus also required.

The second term activities will begin from April 2016, and will include the assembly of a module

for structural and durability design of FRC.

|